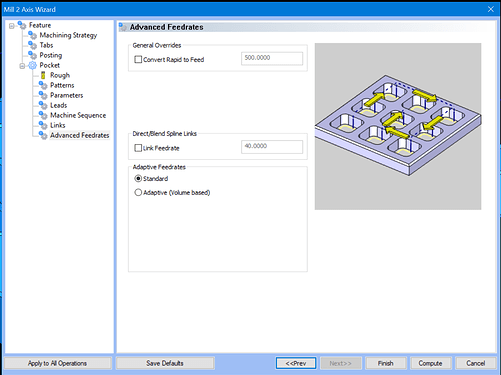

When adaptive milling using an advanced pocket strategy, I’ve noticed that after the tool cuts each pass, rather than lift and rapid to the start of the next pass, it feeds at 700IPM. I cannot for the life of me change it to rapid as it should do. It is costly us considerable cycle time when only feeding at 700ipm versus rapid at 1400 ipm.

Anyone steer me in the right direction here? I’ve used Bobcad for several versions and many many years and this one I cannot figure out.

Later,

Russ