Hello Alex,

thanks for the video. yeah… V34

All understood. It was before.

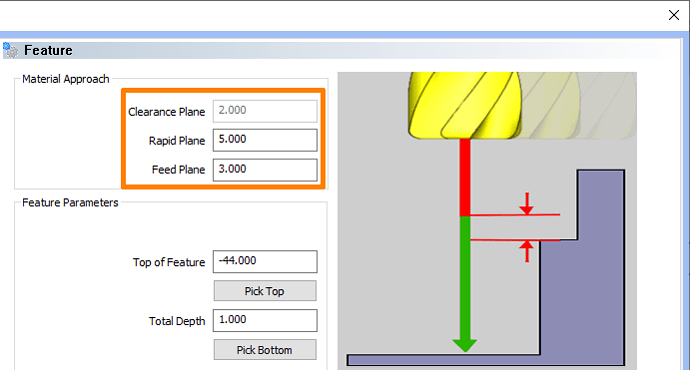

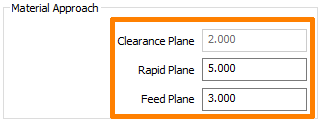

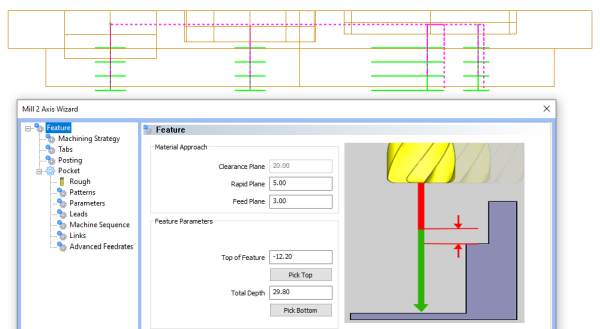

By “bug” I did not mean to eliminate an error from the system, but the elimination of pre-programmed operating errors. Not rarely it comes to pick a “Top of Feature” below 0.00. But also oftne it comes to

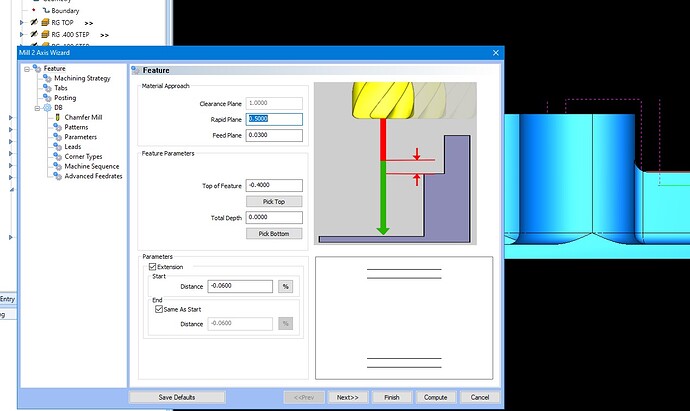

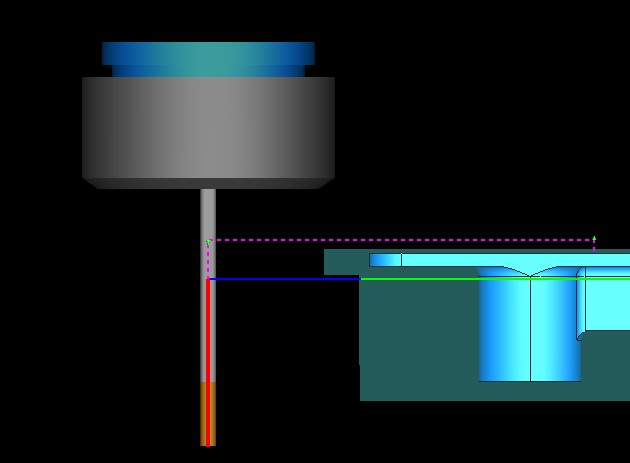

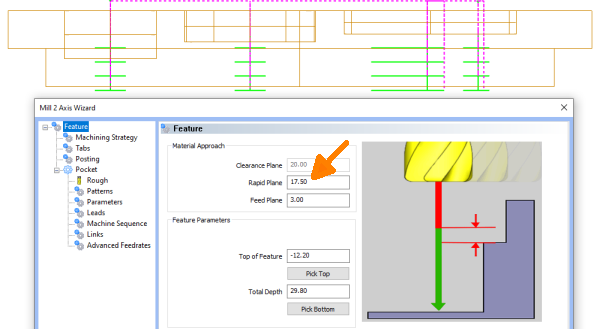

- to a crash, if one forget to correct the RP value (as shown in your video going through the workpiece between upper and lower pockets).

or

- you do group all pockets of different depth and must therefore calculate each RP to get the same (optimized) height or be at least above a crashing route.

It would not come to such problems if:

BobCAM handles the RP as absolute value from Top of Stock and does not change it on its own. If the user wants to, he should explicit change the value hopefully knowing he had done so

At least a warning should be thrown, if “Top of Feature” is changed, that this affects the RP. But still has the risk to simply click away the message and drive a crash.

Perhaps a field lock would also help, preventing a value change. Neither BobCAM nor the user can change the value when the field lock is active (default). But it is the user who can remove/set this lock.

Automation is beautiful and great. Unfortunately, when it results in automatic errors, it’s not.

Bye, Harald