hmm… I do not want BC to destroy the feature as lot of people are already working this way. My extend would not cancel it at all. It would be an improvement for BC. If someone do not want to use it, no problem. He will not have to set a coolant in the Tool Library, which itself stores the cutter parameters with coolant info “unassigned”, that behaves the system to work as usual.

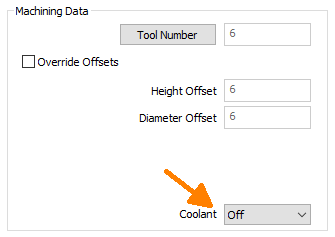

But I know a lot of people coming from other CAM software (me too before knowing BC) build their Tool Library that way, to give the cutter the info to work with coolant (what ever mode) or not. Those people also mainly assign the cutter name like “Wood-Roughing 6mm” using no Coolant. Exactly the same cutter is also good e.g. for Aluminum (and plastic, and …) and therefore a second tool in the Tool Library called “Alu-Roughing 6mm” using Coolant (Flood, Mist, …) will be defined. So choosing the cutter “Wood-Roughing 6mm” or “Alu-Roughing 6mm” there is no need to double check, if Coolant in the “Machining Data” is proper set. I can reflect on the setting within the Tool Library if in “Machining Data” the Coolant will be default set to “Tool” (may be better understandable as in my opening memo called “System”  ).

).

It is not that I write arbitrarily. But BC is the first CAM-Software where I see such a Tool handling Library (including the Material Library; honestley I also do not use, because…!) as BC just does it. And I think to know a lot of other CAM software (including Inventor, VisualMill, SprutCam, …) and all have Coolant be preset in the Tool Library.

IMHO it should be worth a thought to enhance BC this (or at least in a similar) way. there are certainly a dozen or so people out there who want to make a CAM change…

Regards, Harald

).

).