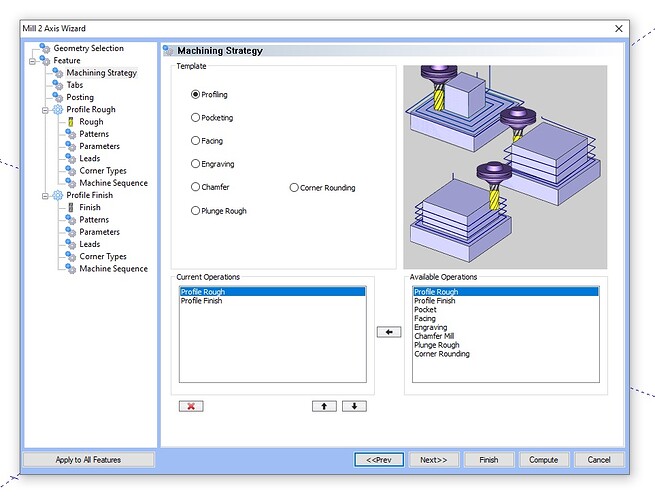

I’d like to see a corner rounding button added to the machining strategy page.

Hello Tim,

The machining strategy page is for selecting operations. Some operations support corner rounding, and some do not.

Could you provide some more details as to how you would expect this option to work, and how it would be applied in the path. I know the dev team would appreciate more details to understand your request.

Hey Tim,

When selecting the corner rounding template you are proposing, would you want it to just have a single corner rounding operation in it?

The reason we chose not to add this (and yes I realize we do have one for chamfer from historical changes) is that typically the chamfer/corner rounding are added along with profiles or pockets.

The depths in the corner rounding and chamfer are set in the operation and not by the feature, so we found it created a lot of confusion that the depth for these was not on the feature page and for the operation so we chose to not make a single template strategy.

Just curious if you use a lot of features with just a single operation or do you use multiple operations in most cases for features?

Hi Greg,

Yes, just add a button beside the chamfer button so when clicked it would put corner rounding in the current options box. I use the chamfer strategy as my edge finish operation at the end of my programs. So instead of choosing chamfer, then adding corner rounding to the current operation from the available operations then deleting chamfer before clicking ‘Next>>’ I thought it would be simpler just to add the corner rounding to the strategy template.

You bring up some interesting points about machining protocol. The obvious one is machining by tool or by feature. I find that a mix of the two work best. For example, machining a pocket 0.500" deep. I pick the geometry and the depth. I rough to depth 0.490" then finish to 0.500" with a second tool, Then profile the walls also with that second tool. If I were to add a corner rounder to the process, lets say with a depth of 0.125", I would have to add a bottom allowance of 0.375" so it wouldn’t plunge right in. So I add it a a separate feature afterwards so it’s easier for me to read and or modify at a later date. At the same time I can also corner round any other pocket at that same depth at the same time by just adding the geometry. Since most of my machining has pockets at different depths, I would have many operations with different bottom allowances which could get confusing. That why I group pockets together according to their depths. Then assign corner finishing to specific depths which could easily be a different mix of pockets than the rough and finish operations.