Hi,

check Fanuc0M_NoM03+M04+M06.BCPst (27.2 KB) instead your FanucoM.BCPst. The PP now does not output a M3 or M4. I also kicked M6 as it might not be useful in your case without turning the spindle

Bye, Harald

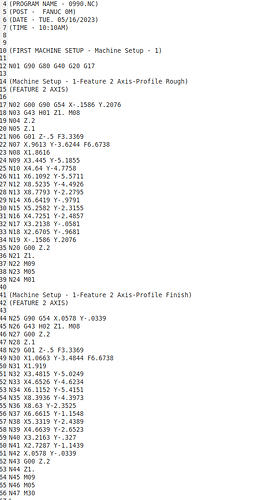

MillingGuy, thank you!!! This worked well, my sample program is profile & pocket commands, I just did not think to include any hole pattern. Before I tried at the mill I used the “find & replace” the MO3, MO4 & MO6 to see if any were found, naturally none were found, worked perfect. I did not try any tool changes, like to ruff vs. finish tool, in sample program, but will tomorrow.

MillingGuy, many, many thanks for hanging in there with me, I am so grateful!!

MillingGuy, many thanks for your help. I have a sample program, 2D profile with a ruffing end mill 1/2" dia and finish pass end mill 1/4" dia in BobCad, the g-code has a MO9, MO5 & MO1 at the end of ruffing cut, but does not stop for tool change. It does recognize the M09, because I see and hear the light & relay for the coolant pump go on, even though there is no pump connected.

I heard that I may use something like the pump relay to control (with additional relay) the hi-speed spindle off/on. But still need to stop program, to change the tool and then “touch off” with a new tool.

Am I correct, I will use the G 54 as the area, of the Fanuc control to change the z axis data that matches the tool change?

Many thanks!

Hi,

I didn’t change M7, M8 and M9 directives so it is normal that if you use coolant with your tool the system generates M7 or M8. As M9 turns off coolant it is no problem when it is used although no coolant activation was done before.

As for the rest I do not know something about Fanuc controller nor do I know your machine.

G54 just tells the controller which workpiece offset the machine should use. G54 is the first one followed by G55, G56, …

Bye, Harald

MillingGuy, thanks for your help! The response below was suggested for the situation I am describing.

“A good code to use for stopping the machine so you can change the tool would be M00. This is a Mandatory Stop. Meaning it doesn’t need any buttons pushed on the control for it to work. M01 if used, needs the Optional Stop Button on to work.”

You have sent PP that uses MO1, can you tweak the PP, so it will use MO0 or I need how to use MO1, correctly, is there something I need to look for to make MO1 work?

MillingGuy, thank you so very much!

@metal2cut when do you want the machine to stop? Easiest way to do it automatically is when you make a tool change within BC. The PP can be modified that way doing a M0 instead of M6. Should it go that way?

Bye, Harald

MillingGuy, this attached file is the sample test file, it has MO1, I think I need MO0 to work proper.

Many thanks!

Harald (The Wizard!!) aka, MillingGuy, you have been extremely helpful, I can’t thank you enough!! This PP worked just the way it needs to, stops at the tool change, I used “handle mode” to move z axis (as if a tool change & touch off, occurred) then back to “start cycle” and it finished the program.

When a tool change is required (I need to understand the “relative screen z value” before & after to use this as the value? Correct) & the z axis in G54 requires an update, because of the difference between the 1st & 2nd tool, z value? Or is there a different way? I will not be using pre-set tools in toolholders, I will be using collets that have no stop on the z variable to make the same z height for both tools.

What I am asking about is the process, so I know what the value (number) is, and from what position (DRO) screen, the “relative” (not the machine position or absolute position) position is the number to write down and insert in to the G54 z value, or do I use the before and after position (the difference) and do the subtraction or addition (the about the 1st tool was different height (+ or -) than the 2nd tool), and use this in G54? Just need some clarification, I have seen YouTube of this, but was a newer Fanuc controller, so it was not completely clear what the number represents. My controller is Fanuc OM.

Harald many thanks!!

I will use the “solution” button soon.

@metal2cut sorry, from sentence “I used “handle mode” to move z axis…” on I can no longer follow what you are meaning and what you want to archive.

I still do not know something about Fanuc or its controller(s) therefor have no knowledge how the machine and controlling unit behaves.

Bye, Harald

MillingGuy, thank you so very much!!! The tool and work offset is specific to the mill, I completely understand. I believe the solution is a few threads up, I checked it off.

Many thanks for your help, Harald (The Wizard!!) aka, MillingGuy!!!