I have an application where I need the spindle not to turn, but the table needs to move per g-code. Attached (using the 4 bolts in the spindle nose piece) to the spindle is a hi-speed 220 volt spindle with manual collet system, that I do not want for all the obvious reasons not to turn, for safety I plan to remove the “v” belts from the spindle to the motor.

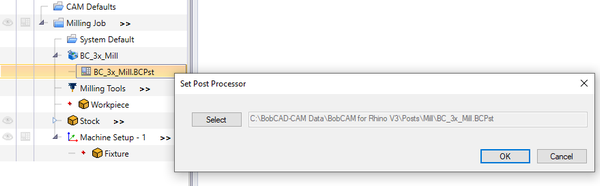

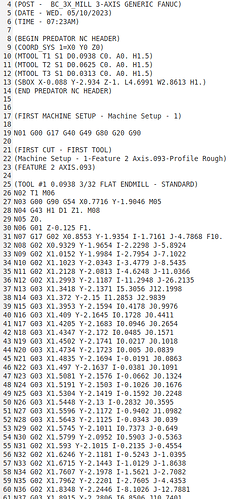

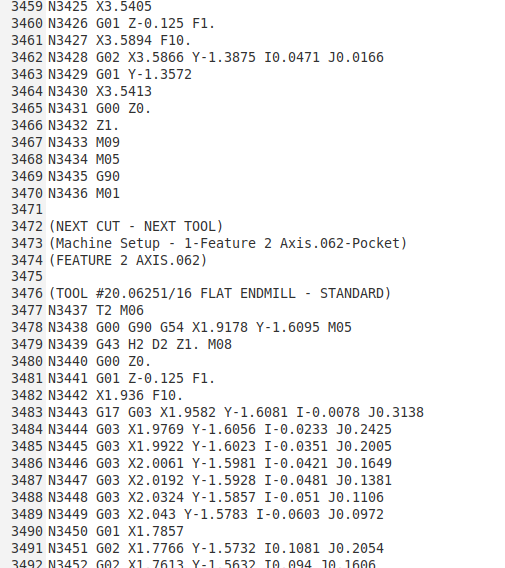

Is there a way to remove all reference to the spindle g-code command after using BobCad to generate the tool path? I know when I program a part in BobCad I am given choice about speed & feed for the tool, but what if I need to have no reference to the spindle to come on.

The controller is Fanuc OM, around 1995, red cap AC drives. In the Fanuc parameter 24.2 = 1 now, I have changed to allow the controller not to see that the spindle is up to speed or not, so it will accept just the x. y, & z axis command and move the table, but must never see a spindle command.

I hope that I have given enough correct information that someone has done this before?