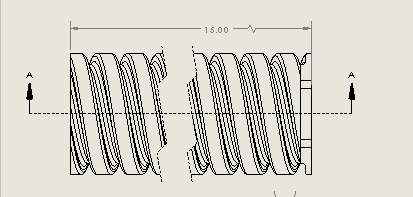

I am new to programming on a lathe and using BobCad-Cam. Our engineering department is wanting me to try to figure out if it is possible to machine an auger on a 2- axis lathe as we are trying to fine-tune an auger design and would like to be able to able to tweak it and manufacture a few one-offs for testing purposes. I am just learning BobCad, and do not have any experience running a lathe or mill at this point, and am feeling a little over my head on this one. Our lathe is a 2 - axis machine, which makes it much more difficult than if it was a 4 axis machine.

I picture the lathe turning pretty slow and the bit cutting along the shaft very quickly numerous times to cut the flighting. The auger that I would be looking at manufacturing would have 2 runs of flighting interwoven with each other and starting 180 degrees offset of each other.

This could also be manufactured on a vertical mill that has a rotating shaft, but we don’t have that setup.

I would appreciate input as I feel like it would be possible, but do not know how to tell the machine to do it.