Hi,

If only lines are used to mill a pocket, how can a finish be done with a clean Lead Out?

My way:

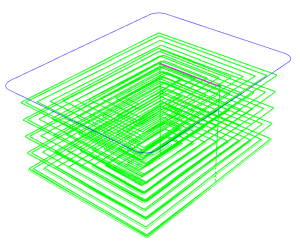

- First Operation: 2 Axis Pocket for Roughing with Side+Bottom Allowance 0.5 to 1mm.

- Second Operation: 2 Axis Pocket for finish with new feature to start quite close to the remaining stock

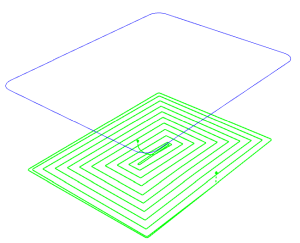

Problem: 2 Axis Pocket just has Lead Entry, but no Lead Out.

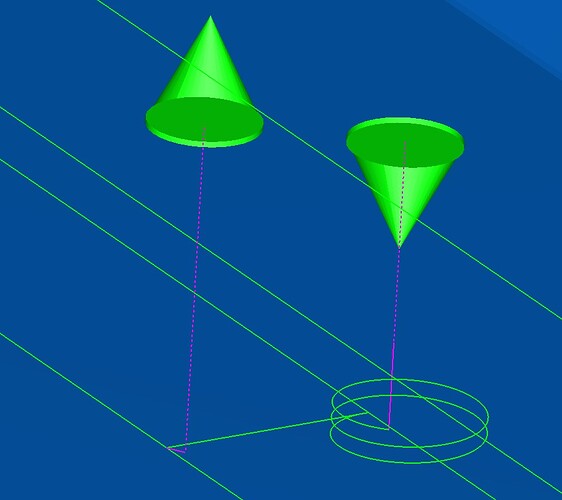

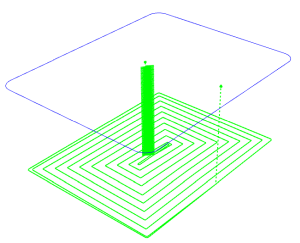

Using Rest Roughing would do the same finish job, but the Entry goes down the whole deepness:

For this it would be nice to be able to set a top value here as well.

For a clean finish I am missing a Lead Out, short traveling inside along a curve and simultaneously lift the cutter not to scratch the bottom.

Or have I overlooked something?

Regards, Harald

Thx.

Thx.