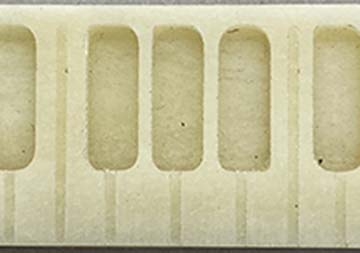

I would recommend slowing down, especially for the finish pass. A tool that small will deflect/bend when cutting and cutting that fast with Mach3 I am betting that the CV distance is giving some some rounding based on the Acceleration/Deceleration to reach that speed.

You want to watch the way the tool cuts in the different materials you normally work with and observe the results when climb vs. conventional cutting. Conventional on a finish pass on an inside profile will sometimes pull the tool into the corners causing not so great looking results. I don’t believe that is what has happened here, to me I think that it’s simply running too fast. OR the machine simply is not rigid enough to keep the tool from wandering while cutting. Without being there and seeing it cut and inspecting the equipment…these are my best guesses as to what is causing your issue.

So, things to try:

1 - leave plenty material on the rough passes so your finish pass can clean up any variation left due to roughing.

2 - Slow the finish pass down so that you feel confident you are not running the machine too fast. Experiment with this on scrap stock and you will find the sweet spot.

3 - I am not sure if you are taking multiple depth cuts, but you could try doing multiple depths for the finish also to reduce the load on the tool to keep if from wandering. Wandering is my non technical term for Tool Deflection. I am not sure if that is what is happening or if it’s the CV that’s causing it. You will have to test to find out.

HTH Alex