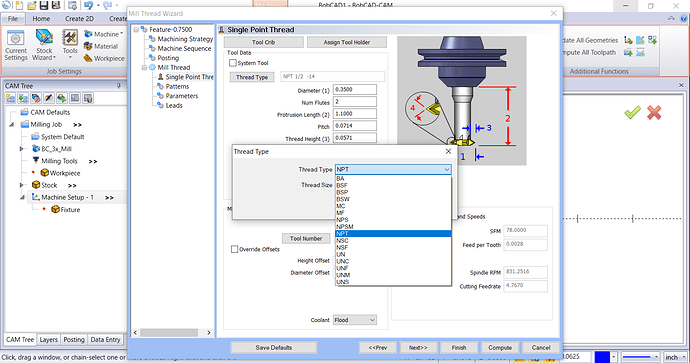

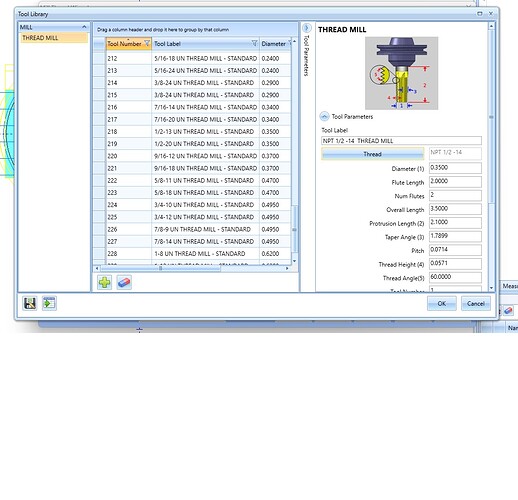

I need to thread mill 1/2 NPT using a acupro thread mill - its not in the thread mill library. How do I use a NPT thread mill?

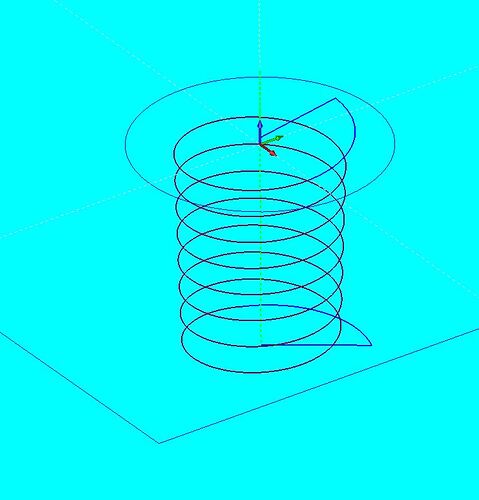

No tapping wont work as the material is a rigid plastic and a tap would just blow it apart and a single point thread mill will take far to much time. I have NPT thread mills with the thread taper built in to the cutter and have made a thread mill tool in BC but the nc code looks like it would for a single point (long code going from the top of the hole to the bottom) I just need to take the mill to near hole depth and interpolate around once or twice. Maybe I should not select NPT in the thread type box ?

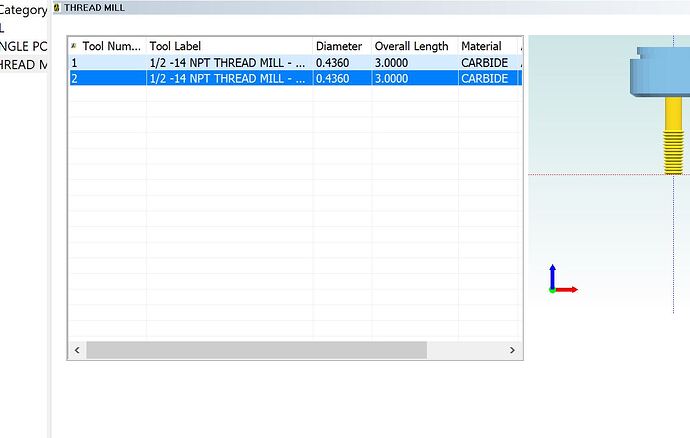

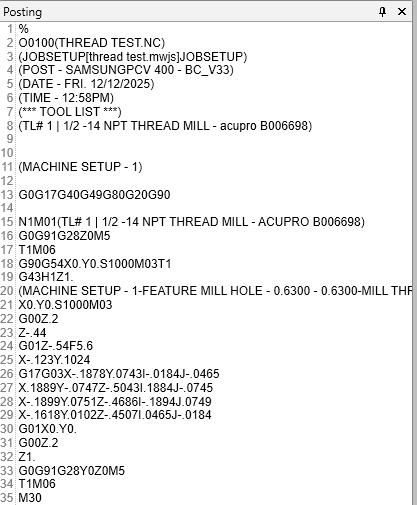

I did add it as a thread mill tool. Thats not the problem, the problem is it creates a toolpath that is 5500 lines long- that points to poinst all the way from the top of the hole to the bottom like its a single point thread mill. I need it to go to feed from the center to near the bottom of the hole and interpolate once or twice return to center and withdraw- like the attached vardex generated file (It wont let me attach a nc file so itsat the bottom)

I can get it to do something that looks like that if I tell BC its a standard 7/16- 14 thread and use the NPT

thread test.bbcd (606.9 KB)

thread mill . But am a little afraid to test that toolpath with my $200 thread mill

O0001(TMINRH CLIMB INCH CYCLES =1)

(Taper=1/32.0 dAlfa=22.5 Second Loop Teeth=0)

(Tool cutting diameter = 0 inch - Mitsubishi Controller.)

G90 G00 G57 X0. Y0.

G43 H10 Z2. M3 S1440

G91 X0 Y0 Z-2.5414

G91 G01 G41 D60 X0.0629 Y-0.0506 F0.23

G91 G03 X0.0506 Y0.0506 Z0.0077 I0J0.0506 F0.23

G91 G03 X-0.0331 Y0.0804 Z0.0089 I-0.1136 J0.0003 F0.78

G91 G03 X-0.0804 Y0.0336 Z0.0090 I-0.0808 J-0.0803

G91 G03 X-0.0808 Y-0.0332 Z0.0089 I-0.0003 J-0.1142

G91 G03 X-0.0338 Y-0.0808 Z0.0089 I0.0807 J-0.0812

G91 G03 X0.0334 Y-0.0812 Z0.0089 I0.1147 J-0.0003

G91 G03 X0.0812 Y-0.0339 Z0.0090 I0.0816 J0.0811

G91 G03 X0.0816 Y0.0335 Z0.0089 I0.0003 J0.1153

G91 G03 X0.0341 Y0.0816 Z0.0089 I-0.0815 J0.0820

G91 G03 X-0.0506 Y0.0506 Z0.0077 I-0.0506 J0

G00 G40 X-0.0651 Y-0.0506 Z0

G90 G00 Z8.0000

M5

M30

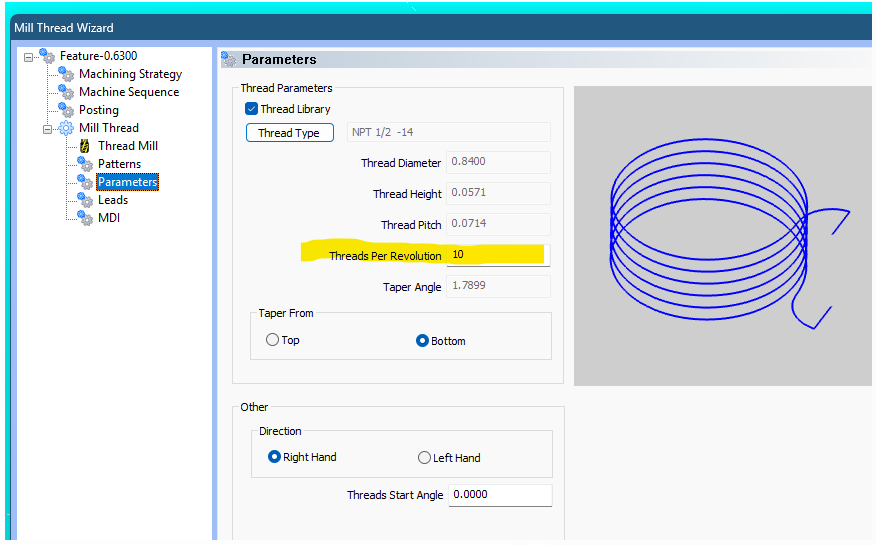

Check out this video I did a while back on thread milling. In this video I cover single point but you can simply alter the Threads Per Revolution to reflect how many threads you will cut per pass if you are using a multi-tooth threadmill tool.

Hope this helps

Alex

Hi Alex, That did help get it to post a smaller program, down to 330 line instead of 5000. But is still outputting point to point even though I have the Arc moves box checked in the Thread Mill Output window. Program is still toooo big to fit in my machine memory so having to drip feed how do I get it to output G2xyzand Rs is that in the post?

Really this issue is more to do with how we handle helical arcs. Currently due to tolerances you get the line segments. Our Development team is aware of this and we hope that in the future here at some point to have a solution that allows us to generate some arcs for this motion.

However I would like to point out that if you are familiar with how arc motion is output for the CNC, if you actually use arcs to cut a tapered helix, you will be deviating from the true path of the helix by some tolerance. By using the line segments you will be getting much more accurate threads cut in the end, however it is at the expense of more lines of code. A tapered helix which is required to cut a pipe thread like you are doing is just simply not a constant arc move. Even when arcs are used, there will have to be many arc segments just to keep the motion within a given tolerance of the true tapered helix. It’s simply a limitation of the arc format used by CNC controllers.

Development is aware of your request along with the requests of some others for this same support in the software. Once they have a good solution I am sure we will see this integrated into the software. With that in mind, I also would like to point out that our research must extend to many types of CNC controllers when implementing options like this. Because there are so many controllers that have so many different options, we must ensure the solution we implement will cover most if not all cases. I say this only to help you understand that what seems like should be an easy implementation, actually takes quite a bit of work for the R&D/Development team.

Hope this Helps

Alex

The leads is to large I think. It looks like it is past your threads

Sounds like another -if you want basic functionality in Bobcad you will have to pony up more money response

Yeah the lead looks f’ed up too. Why does a thread mil toolpath not start , and end at the center of the arc by default???

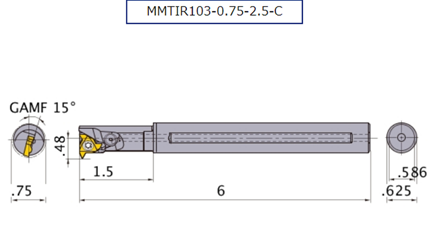

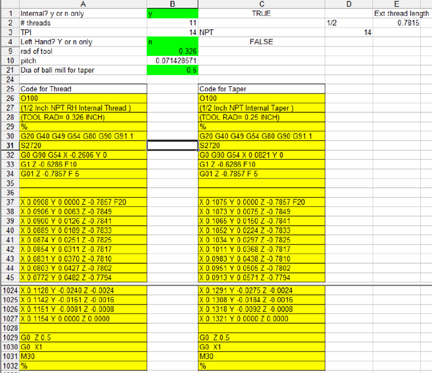

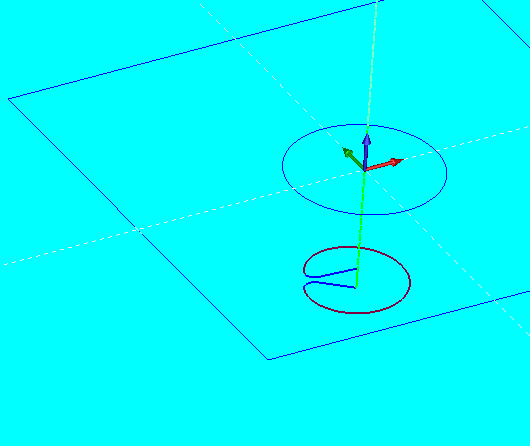

I created an Excel spreadsheet that creates G-code for various sizes of male and female tapered NPT threads. Drill a nominal hole, or turn a nominal OD male part, then set the origin at the center of the hole, Z-origin at top of part, and use a ball end mill to cut the taper. Then use a threading tool to cut the threads. I use a threading insert boring bar in the mill for that purpose. For internal threads the tool cutting radius must fit inside the drilled hole of course, and this tool may not fit.

Just select the nominal pipe size from the sheets, enter the questions in green (internal? Left hand? Radius of tool? and diameter of ball end mill?).

Copy the code in yellow and paste into your G-code file. The tool paths are line segments to get a good fit. The Excel file is in my cloud storage, and I will provide a link to anyone who emails me with a request. Sorry, rules won’t let me post the link here.

Hi Donald,

You probably have this figured out by now, but just in case and for others who may come across this scenario.

When using full form thread mills, in order to have just 1 thread revolution of the cutter, you need to specify on the parameters page the number of cutting threads length of cut of your full form thread mill.

Using Version BCC 36

Hope this helps.

Happy Christmas and New Years to all.

David.