Hi,

perhaps I missed something. Can someone tell me, why for pocket operations a stepover greater than 50% will not mill everything away?

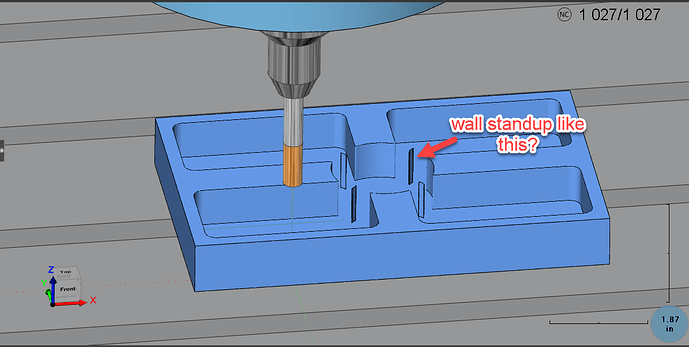

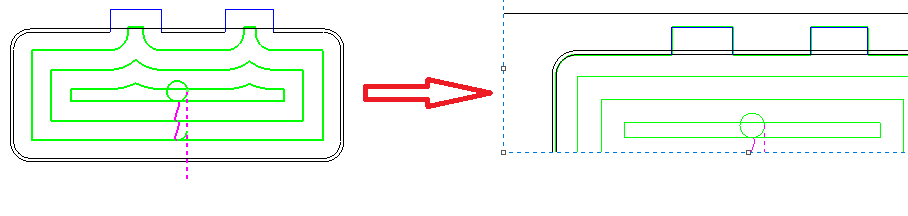

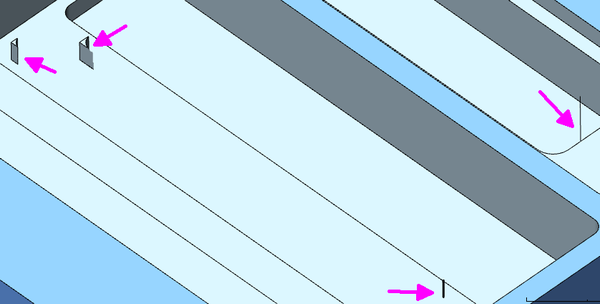

Using e.g. a stepover of 90% you get enormous island not beeing milled. Two problems with it:

- time factor: 50% to 90% means almost doubling resulting in higher costs

- if you have to go down multiple steps to reach the bottom, you get in trouble if than running a stepover with e.g. 40%. the tool will now full run into previous not milled islands.

My expectation is, that even on a stepover=100% all pocket area must be milled (although it is then already clear that the cutter transitions are fibrous).

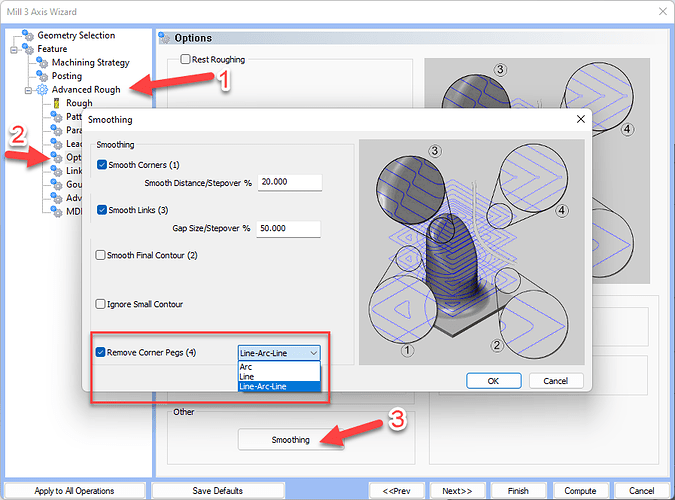

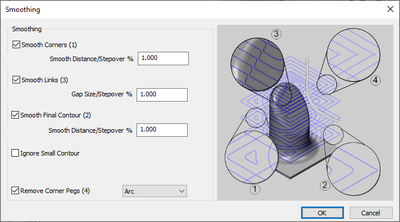

Or is there another way to accomplish this?

Regards, Harald