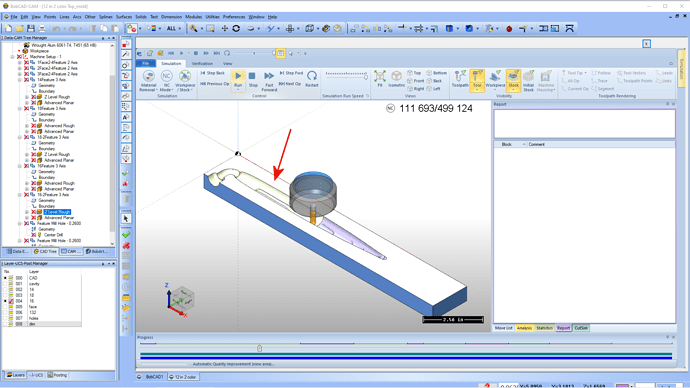

I am cutting a 2 part mold out of aluminum. the cavity i am cutting is 12 inches long by approx 1 inch

diameter not round but an organic shape. I am using ver 29. My mill is a Taig mill using Mach3 .

I am having a lot of trouble breaking belts and endmills. Approx 25 belts and 2 bits, 1/8 and 1/16

I have made 16 molds (32 half molds)

and need to make some more. i have checked the alignment of my belt numerus times and I am sure it is aligned right,

I start out with a 1/4" Ball nose, then to a 1/8" ball nose and final 1/16"

on the 1/8 and 1/16 i am using advanced rough and then advanced planner. on advanced rough i use the rest roughing.

my speed is 10 feedrate, my rpm 10,000

on the 1/8" my DOC is .008 and stepover is .004, then on the advanced planer my cut is .003

this seems insane to me that I have this much trouble on such light cuts.

on my 1/16 feedrate is 6-8 my DOC is .003

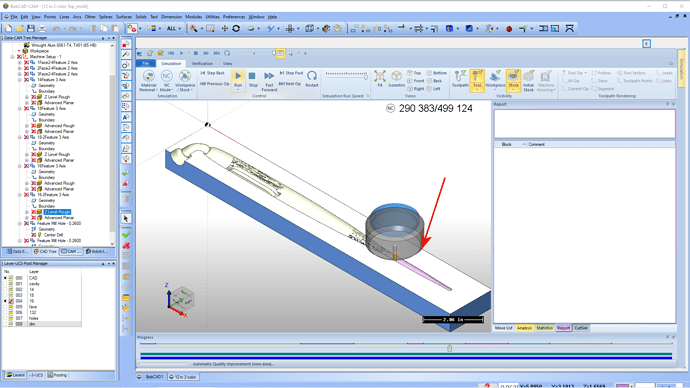

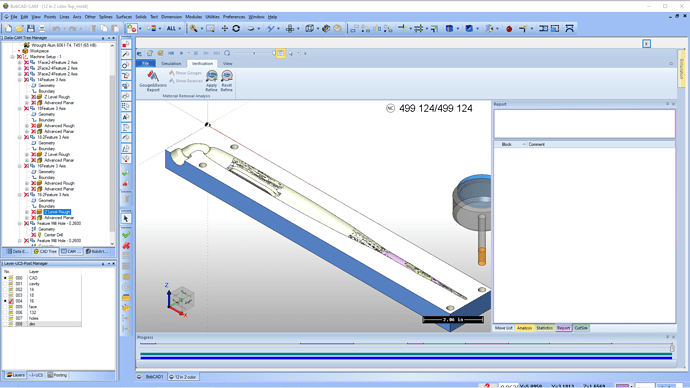

sometimes I don’t break a belt. some of these Feature cuts will run 10-15 hours

these cuts are such light cuts that when a belt breaks it keeps moving, doesn’t throw the reset or break the tool.

i have ran this machine for 12 years and never had this much trouble. but i have never cut a cavity this big.

i have tried the Gouge check and have not had any luck with that.

in the simulation i monitor the report tab that shows collisions and in the 1st several molds it would show a lot of collisions, i changed things around a lot and now no collisions show up.

I tried to upload the file but is too large to upload and i don’t have cloud sharing service.

I would try checking the box my machine does dogleg rapids.