Hi All,

I think this would be important to have and easy to implement.

Feature Request - Run Rough Finish Operation together per Geometry for a multiple geometry feature.

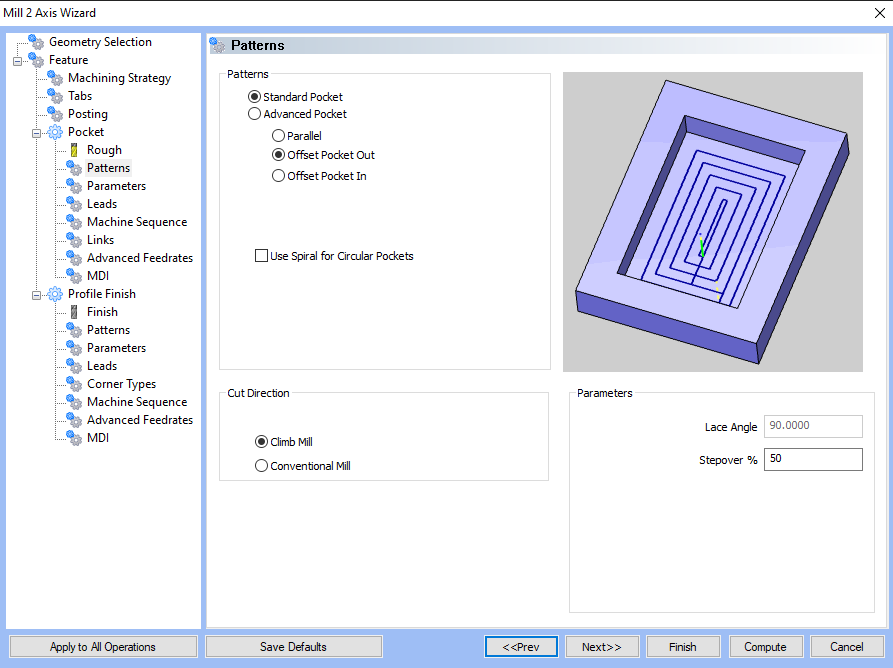

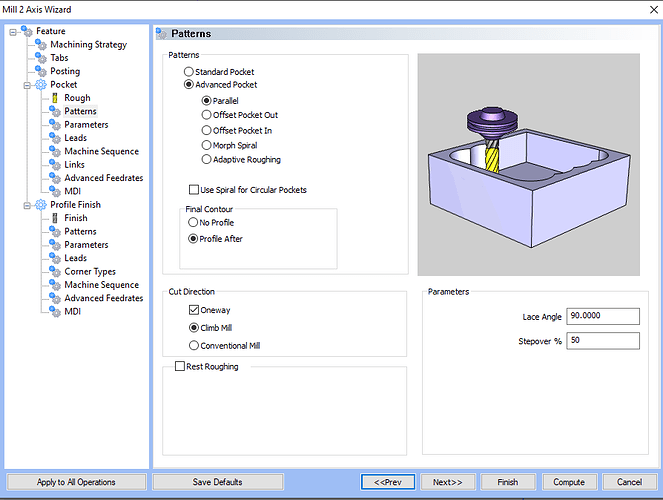

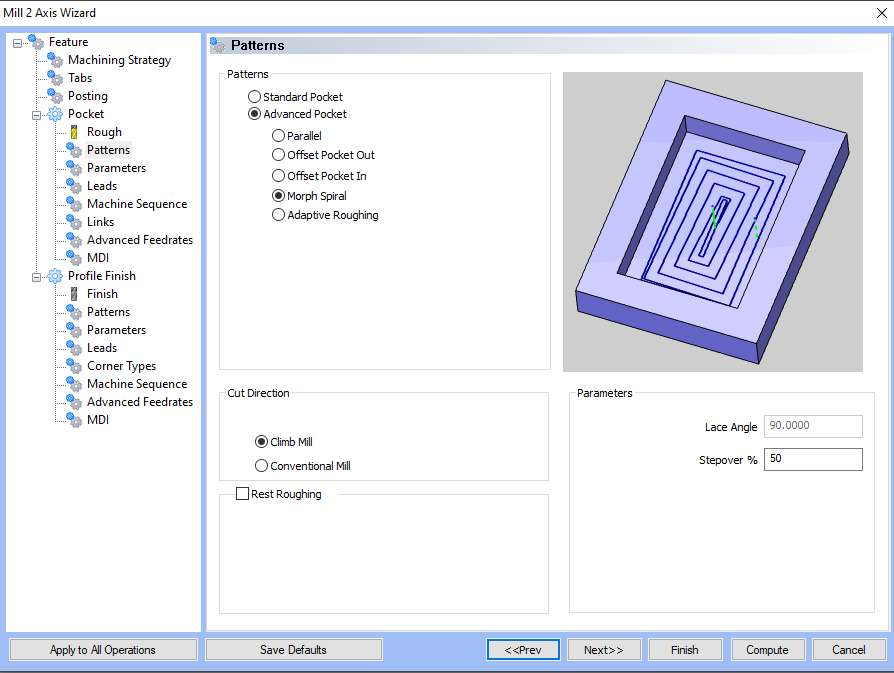

I had this scenario where I was milling a number of pockets that were 3" deep. I was Pocketing to rough them out, then Pocket to Finish the floor and a 2D Profile to finish the walls.

The issue I ran into was that chips packed into the roughed out pockets during the roughing operation and when it came time to run the pocket finish floor and 2d profile operation, the chips in the pockets would cause problems.

So as a feature request , have an option to run selected operations together per geometry instead of going thru the geometry running each op. This is assuming you are using the same tool for the operations.

Thank you.

David.