I am trying to cut a simple slot in a plate of 6061 aluminum stepping down .100 each pass . I do not want to ramp down I want to cut one way Z down .1 and cut back the other way . I have tried every function I can think of but nothing will work I am running ver 31 . I have tried the zig zag setting but it doesn’t seem to work can anyone help seem like this should be so simple

Hello John,

Welcome to the forum.

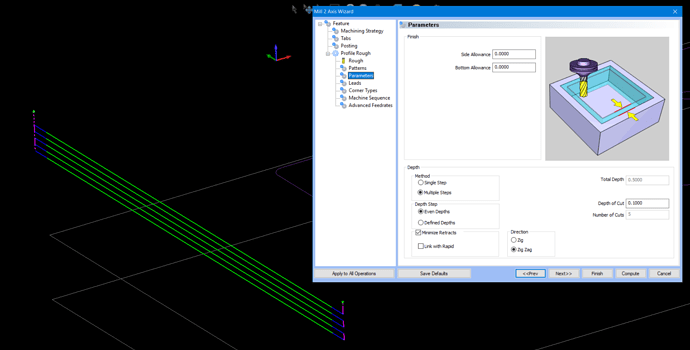

To the best of my knowledge, what you want to do cannot be done in V31, not in a Mill 2 Axis feature. In V33 there were some upgrades to the Profile Rough strategy that allows you to do what you want to do above.

Take a look at the the depth parameters.

David.

John,

May not be simple, but you could copy the geometry z-.100 (times 5 copies for .50 dp). Then calling the 1st z-100 line #1, connect the right side of line #1 to #2, left side of #2 to #3, right #3 to #4, ect, to form one zig zag line. Go to 2D utilities & choose Contour. Pick the end point of the bottom line. Shift select to highlight the zig zag line. Press enter to change zig zag lines to a Contour with start cone at left end point of line #1 and end cone at right end point of line #5. Choose 3D engrave & pick Contour lines.

In simulation tool tip will follow contour from top to bottom. Posted code shows the tools plunge feed rate on the 1st z-100 move only, then the same cutting feed rate for all other linear and plunge moves

thereafter. You should be able to add a different feed rate foe each linear and plunge move if needed.

Hope this helps.

I am also running v31 but have never found that to be a choice