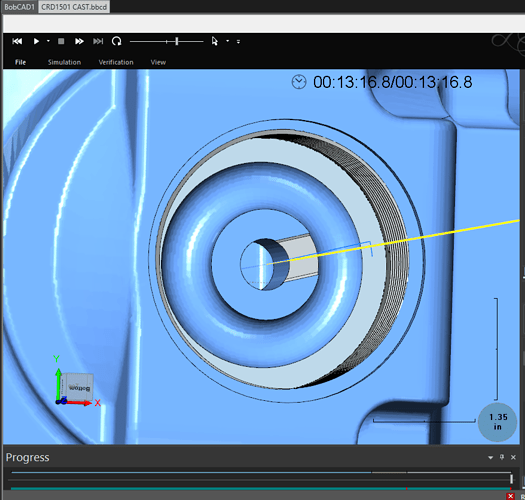

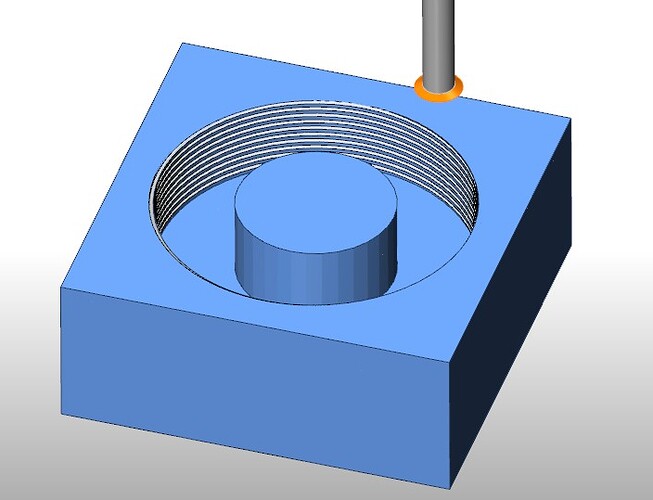

Is there a way to change the start point or the length of the lead in and out in a thread mill operation? It should work the same a a 2D profile or a ramped profile. Other software I have used allow for these adjustments. I have a 3-1/2" diameter that I want to threadmill and it has a boss in the middle that I have to avoid. See image below. Does anyone know of a work around? Maybe I could use a contour with a ramp?

Hi Pete,

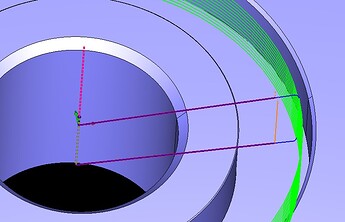

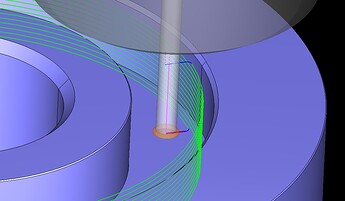

I have ran into that scenario a few times. The only work around that I use is to use the Toolpath Editor.

From the Toolpath Editor,

- break the lead-in and lead-out.

2 Delete the original plunge and leads you broke.

3 Edited toolpath

Hope this helps. Maybe someone else has another way to share also.

David.

I thought you was crazy. but your right Bobcad starts the thread mill from center of hole is what I see

Hello,

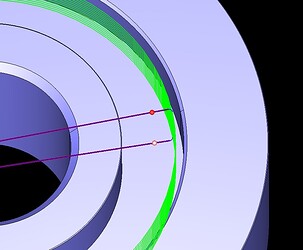

The only way currently to do this would be to use the Toolpath Editor like was previously mentioned. You can access this by right-clicking on your “Mill thread” operation in the CAM Tree and selecting “Edit Toolpath”.

I will put this in as a feature request and let the dev team know about this. Thanks for the input on this!

Be nice to see it fixed, if you are like me and don`t have the luxury of the “Edit Toolpath” function (V28) then one crude, ugly way is to use the boss or create one just for the threading and thread the boss but set the diameter to what is needed to cut the outer wall something like the image attached, like I said, crude and ugly but it does work, just needs a little thought

Hello General,

Welcome to the discussions. Very interesting workaround. Look forward to hearing more from you.

Thank you,

David.

David

Not likely to be posting much, as previously posted I stopped at V28 as it was the last properly stable version that runs reasonably well on the hardware I have.

V29 “fell over” just for fun, V30 and V31 again poor stability, V32 and V33 good but (I reckon V34 will be worse) have become so “bloated” that they require literally thousands spending on the hardware just to run them.

To be brutally honest if I was going to spend the thousands needed to run BobCAD I could just as easily run MasterCAM.

I have used BobCAD since V18 so I have been around for a number of years, the original attraction was one it was very well priced so very affordable for small “one man band” shops, and two it would run on the most basic of computers and never “crashed”

I even stayed around through all the pain of the V2008 that became V22 and the system of having to buy a new version every 18 month/2 years is wearing a bit thin.

Some other softwares now just require an annual payment that gives the user permanent updates/bug fixes/support etc so the software is being constantly kept up to date as long as the annual fee is paid, BobCAD from what I can see want the annual payment and have to buy each new version, no longer viable IMHO for small shops with small budgets

!!!

!!!

Regards

Rob

Rob

Up until this past year I used MasterCAM for over 20 years. It is nowhere as stable as BobCAD. That would be why it is know as MasterCRASH. Yes, you do pay an annual extortion fee to stay on the current release. I do know the software very well and it is very user friendly. I hope to know BobCAD as well in time.

Thanks for the work around it is very useful. Editing my tool path wasn’t very fun either.

Thanks,

Pete

Hi Rob,

That was the thing I liked about Bobcad when I purchased V17. However, I only started using it seriously at V25, when I started my own shop. Now running V33 which has been doing good.

Totally agree with you here. The times I have upgraded, I never felt I was getting good value for the money spent on upgrading, and to be honest in part that was due to how much of the software I used. Basically, Advanced Rough, Flatlands, 2 Axis Mill Profile and Pocketing and the Drill / Tap operations was all I used for 95% of what I do. So when it came to upgrades, I was focused on these areas. Although, there have been many upgrades that are nice, such as the new UI and the NC Editor to mention a couple. Having said that, I think it is a good thing to support the people (the best we can) who make it possible to do what we do in this industry.

All the best,

David.

Not sure about the complaint of having to buy the new version every year, if you buy maintenance it gives you the upgrades and the tech maintenance as well. In October I upgraded to V34 from V31 and got maintenance and was told that as new releases are usually in September, I’ll probably get 35 as well. I started with V16.

Regards,

LaVerne

This right here,my company has 3 seats…and we pay for the maintenance/subscription…and i upgrade to every version…i started on V31…came from 20 years running gibbs sfp(basically gibbs light that came with our fadal)…always had hoped to get a full version of gibbs but that price…this works great for what i/we do here…except…the engraving portion leaves less to be desired…and copy and paste and the tool crib/library is still a mess…but i’m holding out hope…