Hello,

Sorry for the delayed response! Without seeing the actual .bbcd file, it is hard to know for sure what your issue is.

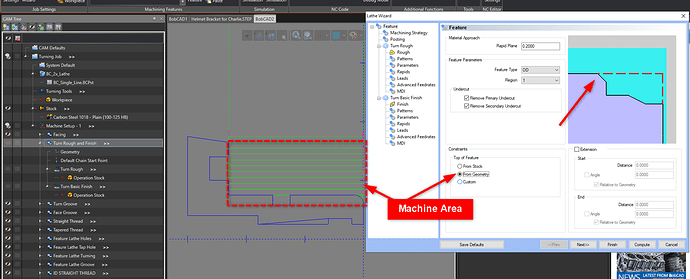

It sounds like you may want to review the “Rapids” and “Leads” page in the feature wizard for both Operations to ensure they are set up as intended. These pages control how the toolpath Enters and Exits the part.

I also wanted to point you to a couple of great resources for getting started in the software.

We have a new Online Learning Center called LaunchPad: https://launchpad.bobcad.com/

We have designed Launchpad by: BobCAD-CAM specifically to help users who are in a fast-paced manufacturing environment to empower them to learn on the go. Launchpad is our new learning platform that provides more segmented, digestible content with interactive features. You can take multiple courses and test your skills and knowledge with digital part file downloads, course PDFs and quizzes after each section to test your knowledge. This allows you to learn at your pace while applying your skills and knowledge right away.

Free Courses: Courses Page

Subscription Bundles: Courses Page

You can start with the V35 Getting Started Course for free here: V35 Getting Started Videos

This course has a Lathe Tutorial video along with other also videos to get you started.

Besides LaunchPad, we also have a Support Site: https://bobcadsupport.com/ along with other great resources that you can find in the PDF download link below:

BobCAD-CAM Online Resources 2023.pdf (208.5 KB)

Welcome to BobCAD! I hope these resources prove useful in your learning process!

Don’t forget to contact our support team as well if you ever need any further assistance with the software!

Phone Number: (727) 489 – 0003

Email: support@bobcad.com