Here are some parts i made at home on my modest cnc mill at home using BobCAD-CAM but I know you have cooler parts than these. Let’s see them!!

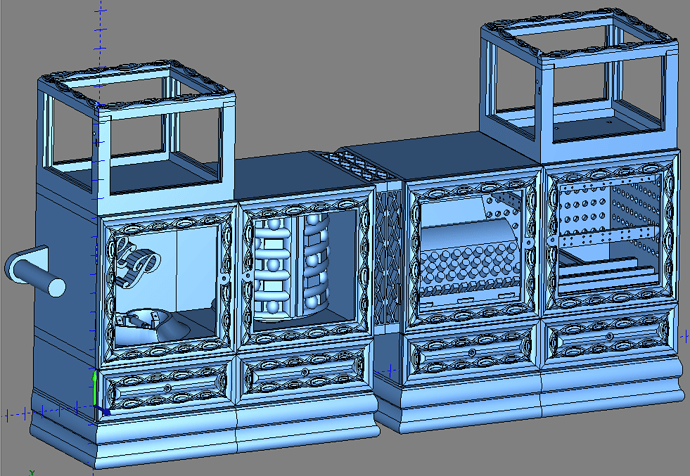

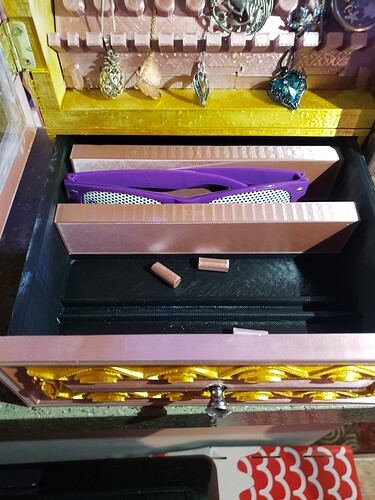

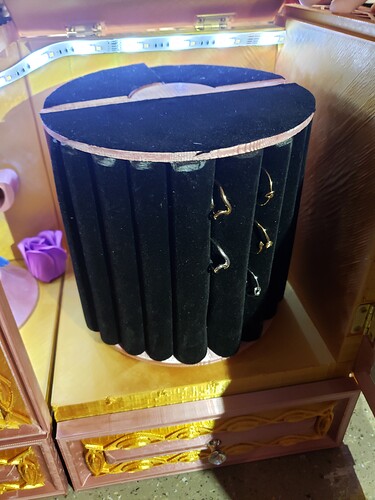

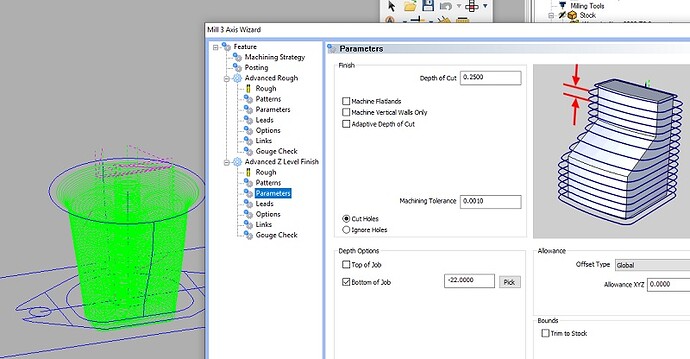

I love using the CAD end of BobCAD because it is simple and straight forward. I personally have a 3d printer and designed this jewelry box in BobCAD. It took 1 month to create in BobCAD and 3 months to print out.

I gave this jewelry box to my now wife as a gift when proposing to her! She loved it of course…and said yes hahaha!

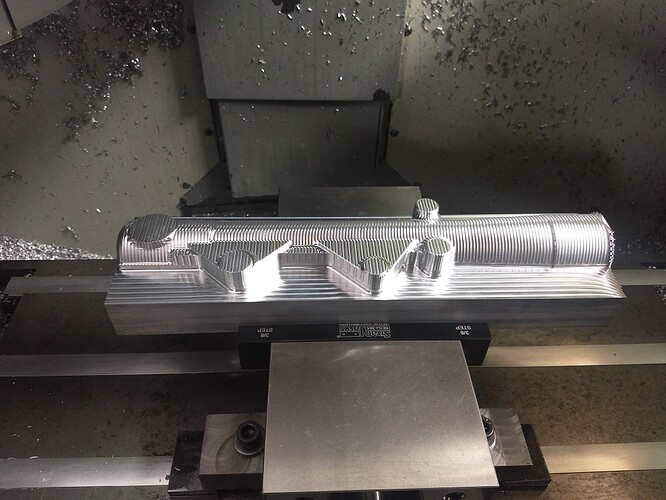

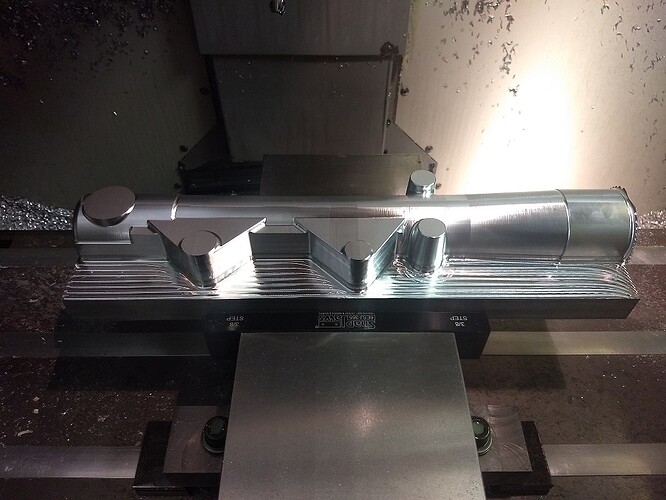

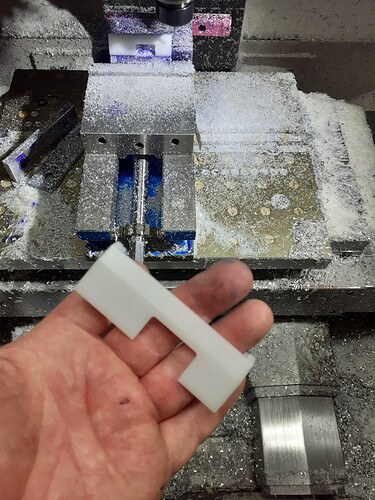

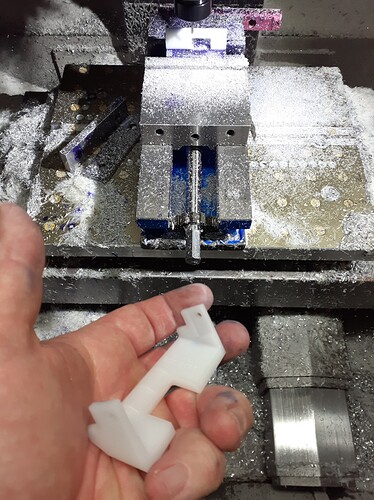

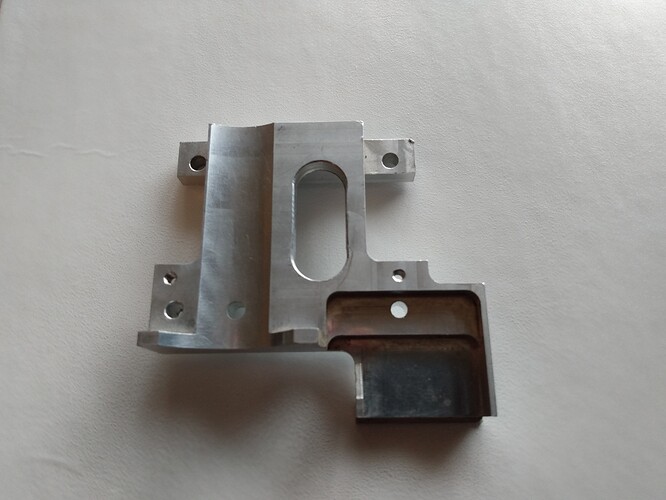

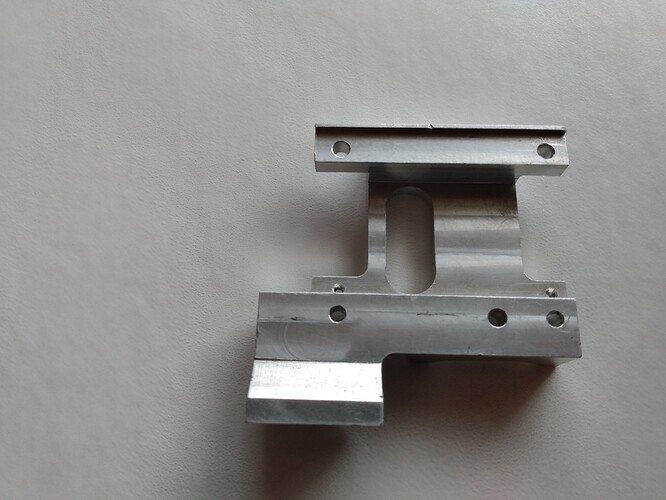

Alex, Thanks. Here are the pics of this part I built several years ago… It is a little shop worn from being tossed around the shop for many years. I was quite proud of this piece and it was the first milling project I ever did.

Steve

Amazing projects! I am a little jealous! I haven’t even been at a CNC machining center for 7 years now and I do miss being able to Program and Machine parts of the like. All I have now is my personal Plasma Cutter. At a cost of $4100.00 for X48"xY33" with Height Control Z3". Mine aren’t as fancy but I will show a couple.

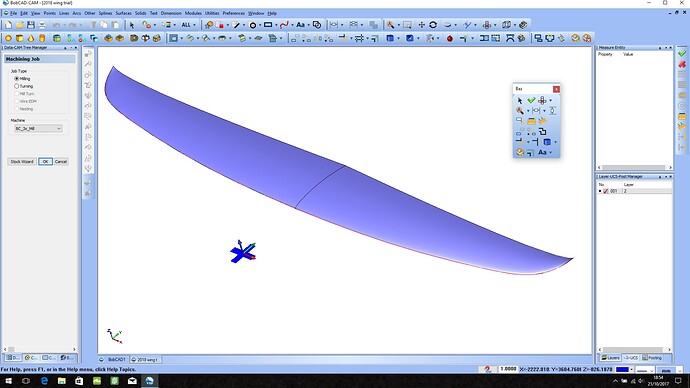

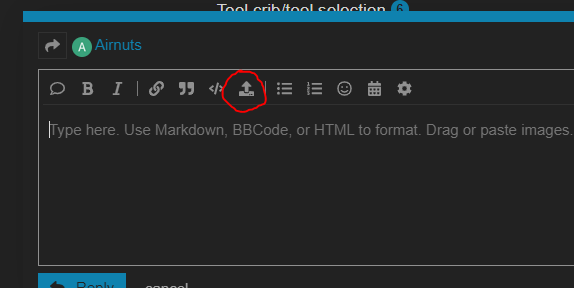

![877181|300x300]Cool, I can see why you have wings on it.

Steve