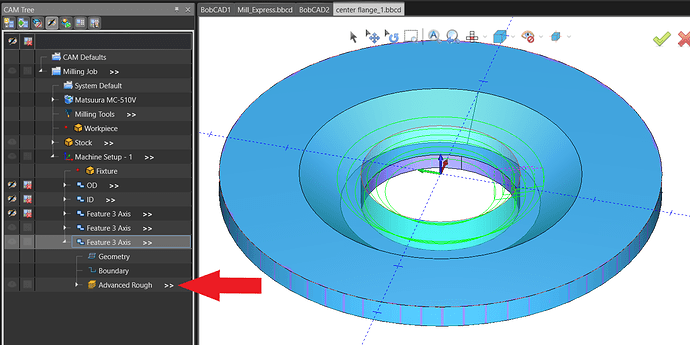

Why am I not getting the cutter paths that I expect? I’ve created an stl file for the part as I can write two lines or three of code for the internal and the external profiles, but now I want to rough and finish the internal profile but I’m not getting what I’d expect. As there is already a hole through the part what I’m expecting is one or two passes around the inside of the taper at each level, I’d like climb milling but I’ll take what I can get. The problem is I get a ‘level’ type roughing and it goes to the center though there’s no material there. When I can get a finish path, the spiral finishing isn’t spiral in any definition I’ve ever used. What am I doing wrong?

center flange_1.bbcd (881.6 KB)

Hello,

The reason you are experiencing the air cutting is because you are using a “Z Level Rough” toolpath. This toolpath is part of the 3x Standard Module. It is a basic toolpath and is limited in its functionality.

If you wanted to keep using the 3x Std Toolpath, you could try to create a smaller circle around the center to represent the hole and add it to the boundary to further constrain the toolpath. However, the 3x Pro toolpath called, “Advanced Rough” works very well in this case.

The “Advanced Rough” toolpath is able to see the stock and trim away extra toolpath that would other wise be air cutting automatically (see pic).

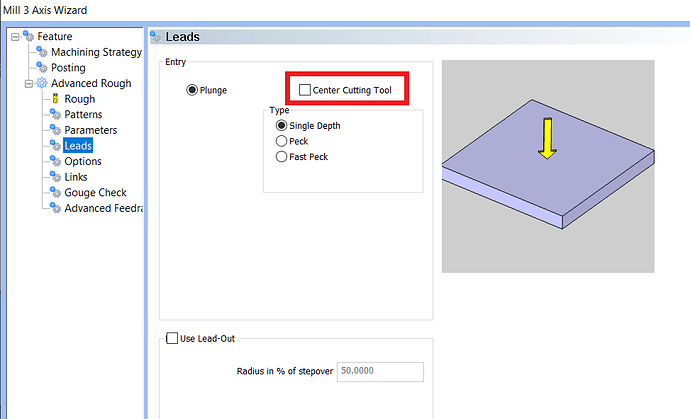

There is also an option in the “Advanced Rough” operation to disable “Center Cutting Tool” to try to get the tool to start from the outside of the part (if there is room), and work its way into the stock.

Thanks, that solves one problem but how do I get it to finish the surface, will the spiral finishing work or should a different function work better?

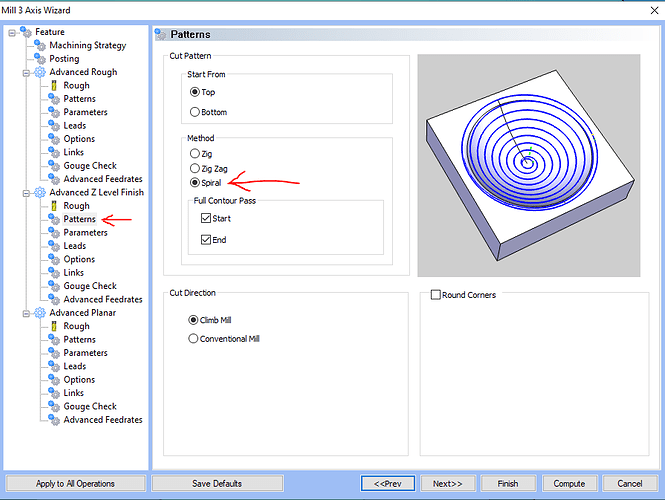

If you have 3 axis Pro license you can use Advanced Z Level Finish, I believe that has a spiral option. I am on my phone now, otherwise I would send a screen shot.

Check the Flatlands box, so it will go all the way down to bottom.

HTH

David.

I have V34 4 axis, obviously not proficient but getting better.

You can just use a Z Level Finish style toolpath. The Spiral Toolpath is really only good for very specific cases.

The Advanced Z Level Finish does have an option to Spiral the toolpath as well.

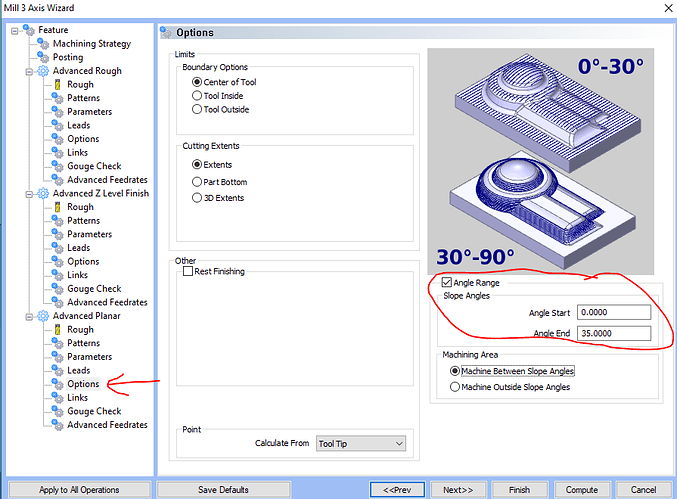

Using Z Level Finish or Planar for 3x Std or Advanced Z Level Finish or Advanced Planar for 3x Pro will work very well for most general cases. Z Level operations are good at machining walls whereas Planar is good at machining floors.

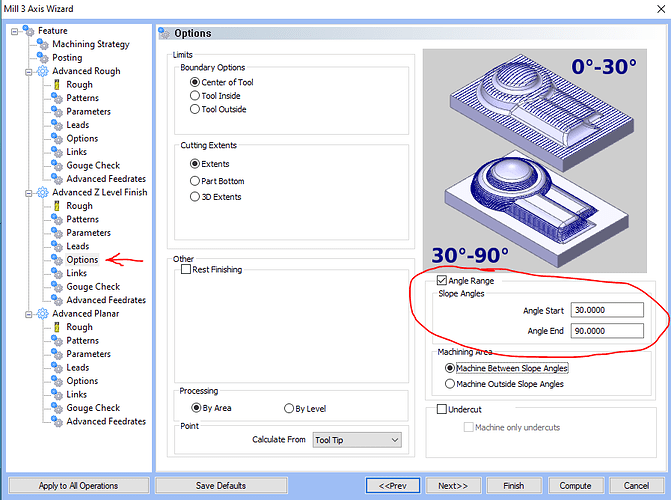

The other cool thing about 3x Pro is that you can set an “Angle Range” on the Options page if you have a part that needs both wall and floor finishing. You can force the Z Level Finish to only get walls and Planar to only get floors by setting a angle range for both operations:

Anyways, hopefully this gives you a little more insight on some of the different operations!

Thanks, I’ll give it a try. I already finished the part on the lathe but knowing how to do it is what I was looking for.