Hi guys,

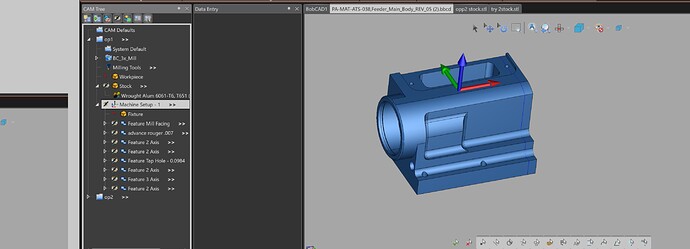

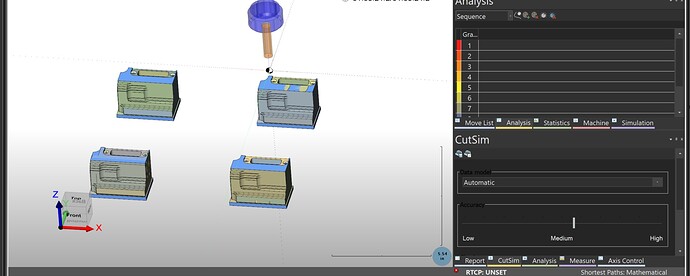

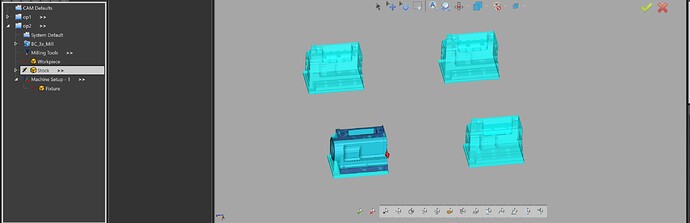

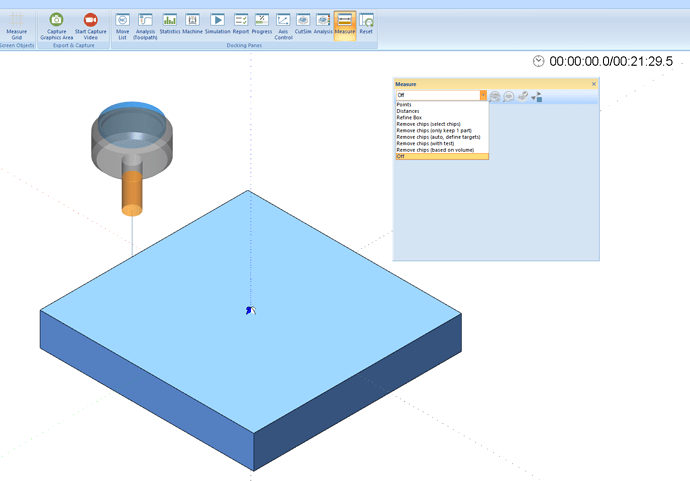

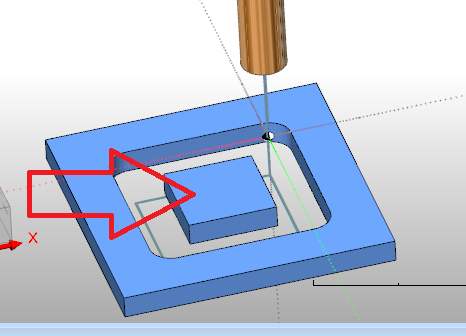

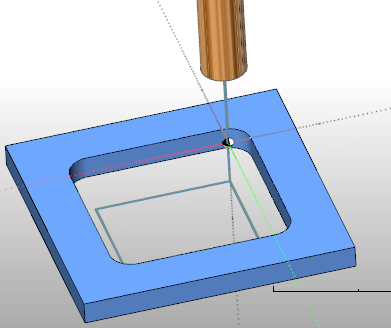

I have a problem with this feature…So I have a pattern using G55, G56, and G57 and when I go into simulation and save the stock it outputs all 4 of the part stocks…how is this any good for work flow?

I am using it in a another mill job but might want to use it as rest machining or 3D machining that sill might be Patterned again…