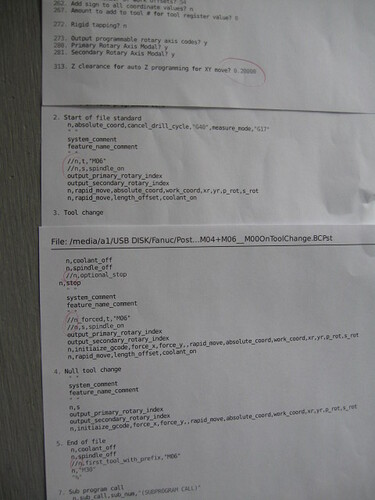

Greetings, I am in the process of learning to load & run programs in a 3axis Bed Mill with a Fanuc MO controller. I have had a 2axis CNC knee mill for several years. With this Fanuc I am using a post processor from “MillingGuy” that allows a 220v bolt on hi-speed spindle (to replace the BT-40), with collet system (so no toolholders, will be used, “touch off” (required for Z axis) each time tool is changed) to be used.

Where I am at is the sample programs I am using will not run all the way until the end of the program. It will stop at line 05 G01 Z-.125 F 57.5. The mill green light will be on, but will not do anything.

How can I get to understand why or to know what the reason is or know what to look for, so when I get the real part I can know how to fix or what is the workaround is. What are the things to look for, my hope is to set a “template” up for each mill, so less confusion.

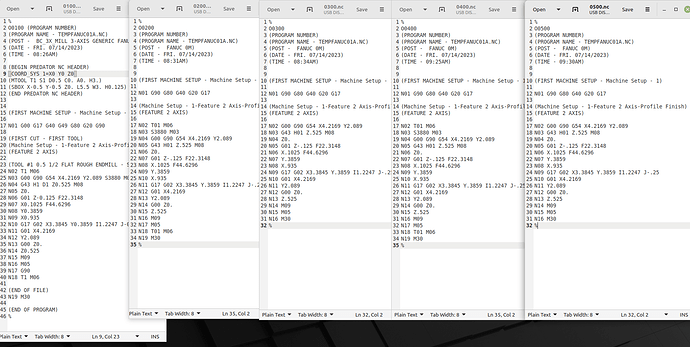

This is the sample program:

%

O0100

(PROGRAM NUMBER)

(PROGRAM NAME - O0900.NC)

(POST - FANUC 0M)

(DATE - WED. 07/12/2023)

(TIME - 11:25AM)

(FIRST MACHINE SETUP - Machine Setup - 1)

N01 G90 G80 G40 G20 G17

(Machine Setup - 1-Feature 2 Axis-Profile Finish)

(FEATURE 2 AXIS)

N02 G00 G90 G54 X4.3732 Y2.2453

N03 G43 H01 Z.525 M08

N04 Z0.

N05 G01 Z-.125 F57.5

N06 X-.0537 F115.

N07 Y.2296

N08 X1.07

N09 G17 G02 X3.2494 Y.2296 I1.0897 J-.0938

N10 G01 X4.3732

N11 Y2.2453

N12 G00 Z0.

N13 Z.525

N14 M09

N15 M05

N16 M30

%

Many thanks in advance for any suggestions!