i’ve noticed that when i save machining strategy templates (which i’m doing more and more it seems) i find that when i pull said template back up…it’s really quite hit or miss(more miss than hit it seems) as to whether it will have the tools in there that i put in there and the speeds and feeds are still correct…this post might go along with the tool selection posts that i’ve put up…really hoping that this all can get handled soon…i guess got spoiled with the point and click ease that Gibbs had…

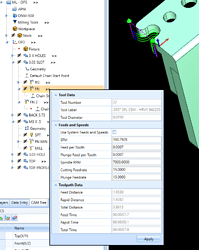

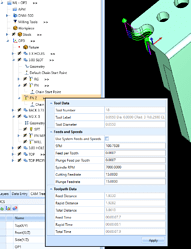

Bigman I also work with templates a lot. And have not seen the issue you have (will keep a close eye out now). But what I have noticed with my templates that when I open them it will check the box for use cutting Condition wish is a box I always uncheck and then default all depths to .500.

today i was working with a program…it was a inset hole in a blank…i was cleaning it up after the engraving…(a pilot was just drilled and then blank engraved and then back to me to finish the hole)…i was literally using the same program…just moved the hole and my depth values went back to their defaults…it’s maddening sometimes…

I agree and why set it at .500 why not 0.0

Hey @Bigman, would you happen to be experiencing this only when working with Drilling or 2 Axis Features?

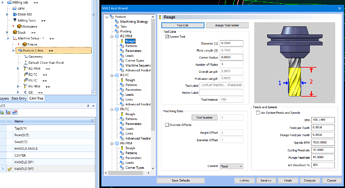

I understand that a good percentage of our customers do not love our current tool assignment methods when creating new features (whether it be created from scratch, from a saved strategy, copy/pasted, and the many ways of creating features and operations.

BobCAD’s methods of looking at the hole sizes, hole depths, and so on for drilling to grab the appropriate tool from your tool crib or tool library, as well as looking at the depths for the Mill 2 Axis features to assure the tool you have assigned has enough flute length to cut the part is sometimes hugely beneficial and as we see here, sometimes very confusing to the expectation that the same tool should always be there when using things you have saved and loaded in whatever method.

Was the inputs geometry for this just a wireframe arc?

i will say whether drilling or milling…it rarely if almost never picks a tool from MY tool crib…it almost always just creates one on it’s own accord…but then the issue that prompted this post was i had an existing program that i had run…just needed to move one hole…used save as to save the program using the new name…moved my hole and then looked at the operation and sure enough it reset to default values…but at least the tools stayed the same…if i copy and paste an operation from one program to another…on drilling it resets to default values…on milling it just scrambles and creates cutters on it’s own, which if one is not careful results in hilarity in the shop if not caught before hitting the green button

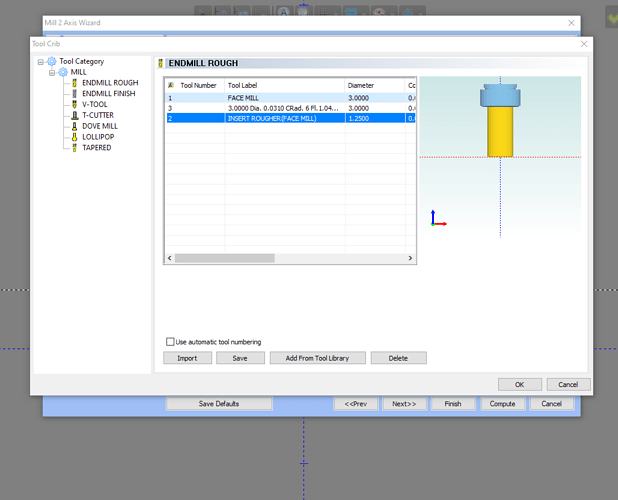

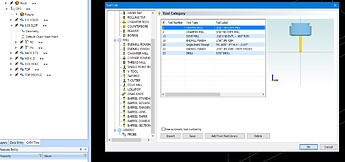

here’s how maddening this is…i literally had an operation which was a saved template for a facemilling op…and it picked the correct tool…(even a broken clock is right twice a day)…then i go to my next saved template and does it pick the tool i saved in the template?..NO… does it pick my facemill that’s already in my crib?..NO Again…but…it makes the exact same tool as my facemill and stick it in my crib…i’ll ask again…WHY…i would rather have it not pick or make a tool at all…luckily i most always catch it before the obvious hilarity would ensue…make it stop…!..for the record…tool number 2 is the one that should have been picked as that’s what’s saved in the template Screenshot 2021-10-20 130600|618x500

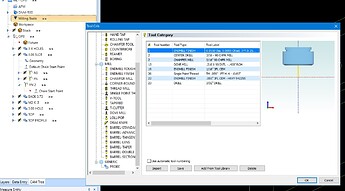

Ran into the same situation, but with a 2D Profile… I did a copy and paste of a profile into the same feature, that’s right the same feature… and it just makes up the same size tool and gives it a different label and a different tool number (even though Automatic Tool “Numbing” ) is unchecked.

Before Copy and Paste

After Copy and Paste into the same feature

THE WHOLE COPY AND PASTE AND TEMPLATE THING IS POINTLESS IF IT CONTINUES TO DO STUFF LIKE THIS…at this point i’m just going back to everything is just going to be a new op…screw the templates and copy and pasting ops…i just end up deleting them and starting new anyway

Thank you for the information. It will help a lot if could also share the screen copy of your Tool Crib for this problem file, or even the .bbcd file if possible.

Understand the frustration, wondering if it is OK for you to share the saved template having tool problem, and also which BobCAD version you are using? Thanks

as far as the version…it’s V34…as we have a subscription i update regularly hoping against hope that this will be fixed…but was told as it buried so deep in the software that it’s hard to fix…

Hello xqu,

Here is the before and after tool crib screen shots, also file is attached.

Thank you.

Before Copy and Paste

After Copy and Paste

File

mount V33.zip (1.8 MB)

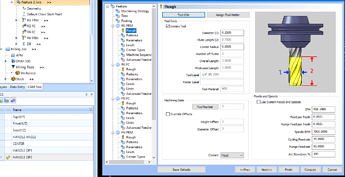

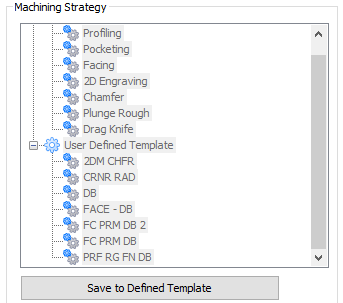

Since this post was originally about Tool selection issues with User Defined Machining Templates, I did some testing.

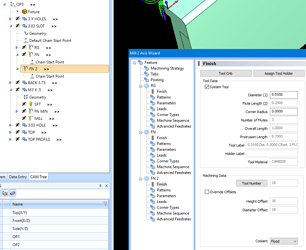

I found that when you use a User Defined Machining Template within the job it was created and saved in, the tool data is unchanged, except the System Tool box will be checked.

However, if I used that same User Defined Machining Template in another job in the same file or another file, just as @Bigman stated the Tool Data is changed out for a tool that is the same diameter, but with different length, # of flutes, flute length and label. i.e not a true copy and paste

Speeds and Feeds remained the same

File 7 X 7 PLATE JOE.zip (929.0 KB)

User Defined Machining Template FC PRM DB 2.zip (2.3 KB)

Hello Eric,

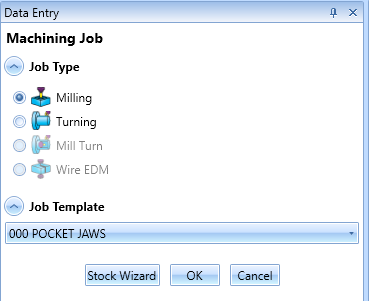

In this case when you say templates, do you mean User Defined Template, in Machining Strategy in the Mill Wizard

or a Job Template

My experience with Job Templates has been fine when it comes to the Tool Selection issues discussed thru out the forum. The only thing I would have to do is uncheck Auto Tool Numbering.

i’m actually talking about the user defined templates in the machining strategy…i had been setting those up because i have several series of different parts that i would use the same strategy on…pockets…perimeters and such…i don’t remember it being this bad in like version 31 or 32 really…tho it’s tough to remember back that far…

In the case of the drawing I posted I just did a feature copy and it changed my tool with in the same program.

Thanks for the file, we will look into it.