Hi all, The problem I am now having is everything I create runs so slow it is just about useless. I guess the question is; my wall charts all show about .001 per flute. on standard steel. I am using a 4 flute cutter so apparently when I use the feeds and speeds on the tool crib settings or default to manual and enter .001 the code generates as .001 instead of .004 as it should. Is this something everyone has experienced and should I manually enter this as .004 to get the output where it should be. I would think the software should know it is a 4 flute cutter and out put it to the post as .004. Did not do that this time. It is not defined anywhere I can find. Any wisdom out there. Thanks, Steve

FWIW, I almost never use the system feeds and speeds, there are though, a couple of programs that will help selecting proper feeds and speeds. There are Gwizard and HSMadvisor, each has it’s strong points and neither cost much, both only give best estimated feeds and speeds based on your input, look at them both, it will be worth your effort. There are others, at much lower prices but these two programs have had considerable effort put into them, in the end, you get what you pay for.

L98fiero,

Thank you for your input. I will go and check these programs out. Regards,

Steve

The best place I think of to go is the Tool Manufacturer with all the informmation/specification off the CNC that is being used.

Your wall chart is pretty irrelevant if for example your Spindle doesn`t have the “grunt” to use the published settings, go talk to the people who make the tools, what I will always try to do is get the manufacturers rep to come into my shop and actually see what the job is and what is required. I agree, not always possible but I have found that is often a good route to go as they usually have good experience and knowledge of their products. Just IMHO

you can make a tool crib that will put out the right numbers every time. Takes way to long to look that stuff up for every job.

Honestly, I use Helicals machining advisor even if Im not using their tools. ill just go to their website find a tool similar to what Im using and enter the edp #. It gets me close and its free. For Ferrous materials i have grown knowledge, and know the ball parks. I never even select the material to try and utilize the feeds from bobcad.

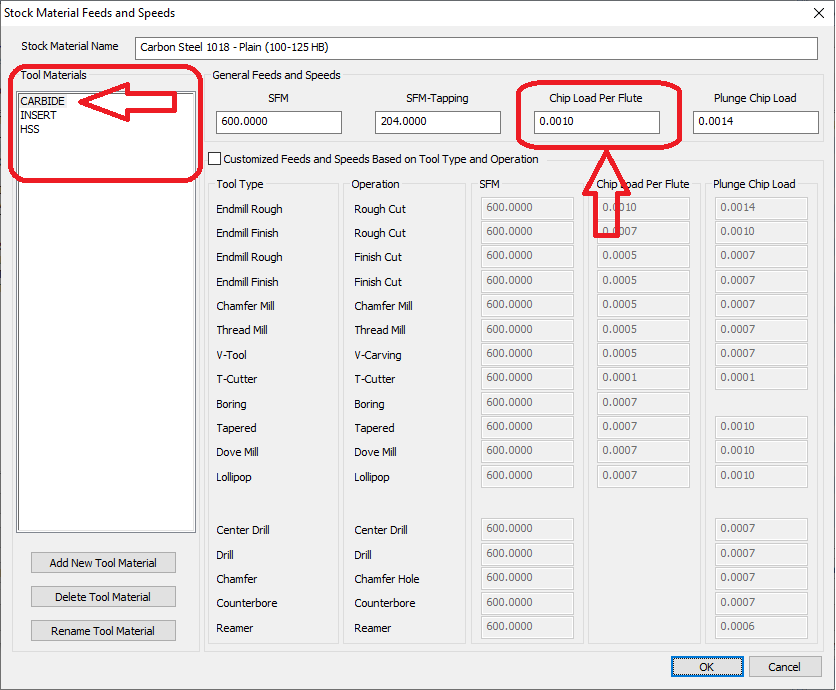

@Airnuts I am wondering if you are setting up the material settings correctly as the system does take into account the number of flutes on your milling tool.

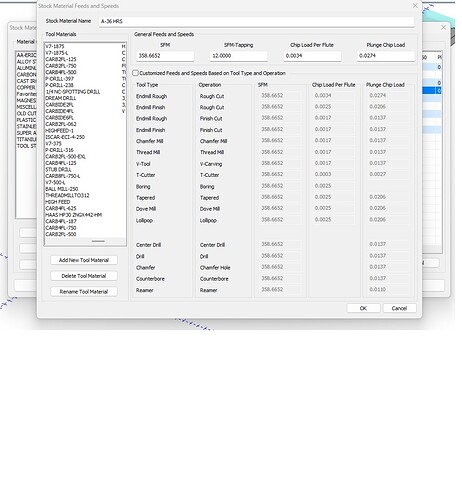

In the material library you select the type of workpiece material you are cutting. When you go in and edit each workpiece material type there is also a section on the left where you define the Tool Material type. This is very important as you can set different values based on if the tool is Carbide, HSS, or an Insert cutter. (Those are the default tool material types).

When you go in and modify the Chip Load Per Flute, you need to make sure you are changing it for each/all tool material types appropriately. Then in the operation where you are programming, make sure the tool you are selecting from the tool library is made of the correct tool material type.

I often see people not pay any attention to the tool material type and this causes the speeds and feeds to not be accurate for them.

Hopefully this helps (HTH)

Alex

Thanks, everyone for the input. I did get this working and as above I did use the recommended cutter speeds from the tool manufacture. I’m noticed there seems to be a confusion in terminology showing up between Inches per Minute and feet per minute. IT does not seem to be a consistent input across the board between the charts I have and the software etc.

Regards,

Steve

HI

You can’t always go off MFG. charts either. I have some HE ball endmills from a reputable company that list an RPM of 233,000+ for an 1/8" cutter.

I have had to watch the system feeds & speeds very closely, the chart above has a SFM of 600 for 1018 and a plunge of .0014, I have an expensive pile of broken endmills that says otherwise.

IMHO the tool/material/toolpath is linked a little too loosely for my taste and if you aren’t paying attention you can end up with a default material and inappropriate feeds and speeds.

I have been told by many that it depends on the machine and how rigid it is and the coolant your using. In one case recently while I was trying to sort this out I was trying to use a 1/2 inch 4 flute cutter with cool mist. I was obviously too much on RPM and it just melted the end of the cutter. Now I know it was too fast and that it wasn’t getting cool but it was also a 4" length and before with a 1 1/2 length tool it cut at the same speed. Its all magic for sure and a lot of luck. One thing I think now is you just can’t push things to fast or they will destroy themselves. This is where the experience comes in, but you have to buy a bunch of cutters before you get the experience. Steve

Hey guys,

Lots of great feedback in this discussion. Feeds and Speeds definitely come with experience on your given machine.

However, I also wanted to give you guys a couple more resources you can utilize when it comes to feeds and speeds, see below:

- Knowledge Base Article: Feeds and Speeds in BobCAD-CAM

This article covers how to setup Speeds and Feeds in BobCAD-CAM. It covers the Material Library, how the g-code gets posted out, how to manually assign Feeds and Speeds and the math behind the Feeds and Speeds when you adjust the values manually.

We aren’t currently partnered with cnccookbok.com. However, I know many of our customers use this tool to find Speeds and Feeds more effectively.

BobCad’s auto speeds and feeds is totally useless and a complete waste of time.

An example for you is this:- a 10mm dia cutter as a feed rate of 0.028 fz but a 20mm dia cutter as a feed rate of 0.038 fz.

These are manufactures machining info.

BobCad only allows you to set one value in the automatic speeds and feeds table, if you enter the lower feed rate the bigger cutters will rub and wear out, if you enter the higher value the smaller tools will break. So the automatic feed and speed tables are a complete and misleading part of BobCad.

So just enter your own feeds and speeds for every cutter and remember if you change the size of your tool at a later date you must update the feed and speeds for this tool.

Hi,

Please share your table and explain how it works for different diameter cutters.

ie 25mm dia cutter (1") and 3mm dia cutter (1/8") which both require different cip loads per tooth.

And different feed per tooth values, as I can’t seem to get BobCad to generate this values.

Thank for any help you can give

Steve

HSM Advisor.Depending on machine,you might reduce %10 to %15 percent.Easy to use and a lot of thought went into it.

maybe it’s just me…and i’ve been in the biz for a while…but i never use BobCAD’s table for setting speeds and feeds…i’ll maybe use the MFG’s numbers as a starting point…and adjust for material and type of cutting condition…i almost never just poke and hope

I am the same way. There are too many variables for Bobcad to be effective. It would be neat to be able to import a tool library from a tooling manufacture with the feeds and speeds recommended for the tool. I have been 3D printing and use fusion for this, I poked at their CAM and noticed you could do this which was cool. The actual CAM though did not hold a candle to bobcad.

A few questions for you all on this topic:

Please reply with a short list of what you find lacking in the current speed/feed values and options in the BCC products (Mill and Lathe)

Then also let me know:

How many of you have used the HSMAdvisor application you mentioned?

Do you like the interface and find the values to be good?

What about Gwizard?

Do you like one vs the other?

What do you like and not like about each?

This info can help the R&D team to evaluate options and solutions so your feedback is very much appreciated.

Alex