Hey,

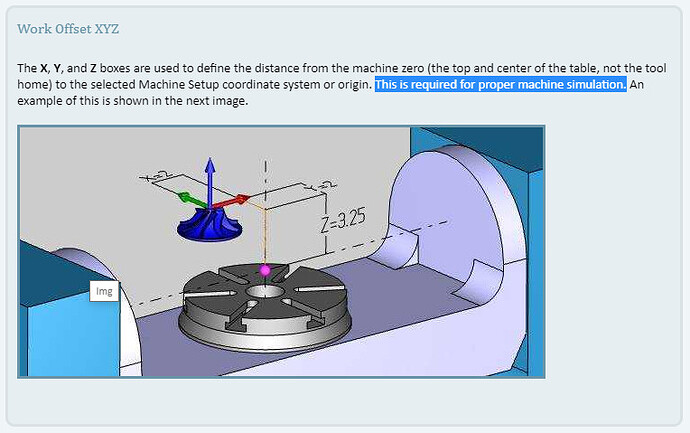

So the work offset value affects the simulation for sure. If for example, say you have the machine setup on the top face of your stock and try to simulate, the stock will be inside the table of the machine. The work offset coordinate is the relation from the machine origin to where the stock should be on the machine in simulation.

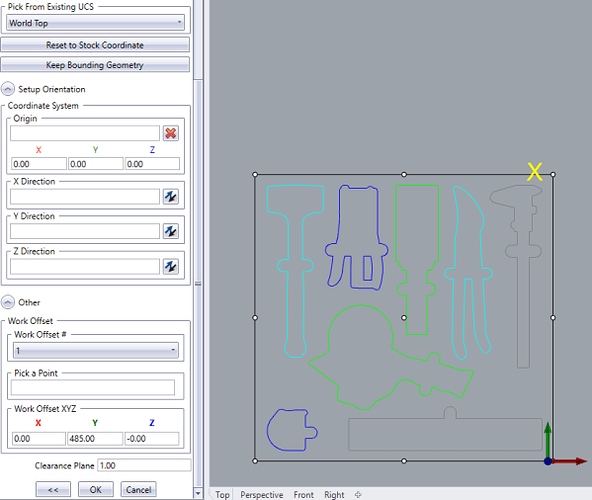

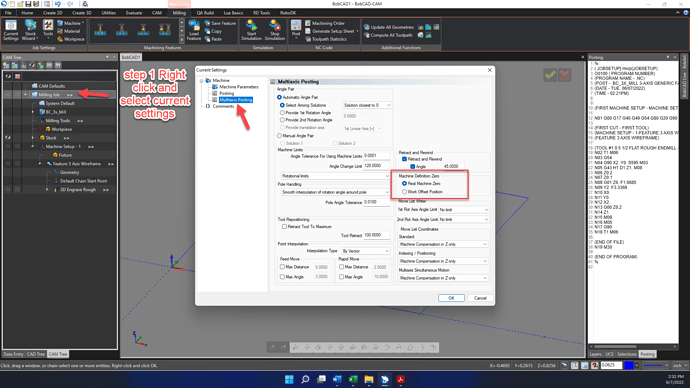

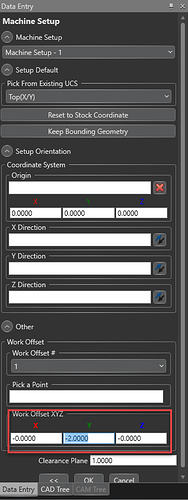

However, there is a option in the Multiaxis posting page which you can get to right click on the job and selecting current settings. You will see on the right side under Machine Definition Zero option to post relative to the Real Machine Zero which is all coordinates are relative to the machine setup location or the Work offset position which when this option is selected, all coordinates are output will be relative to the work offset values specified in the setup page. So the work offset values will be added to the coordinates from the machine setup location

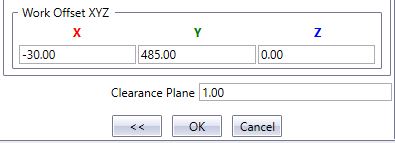

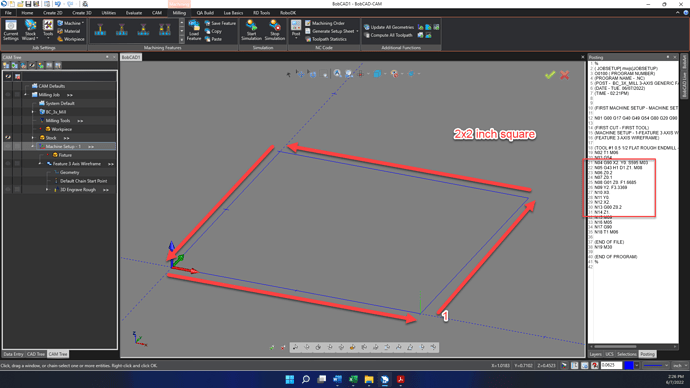

So for example, here below i drew a simple 2x2 inches square and threw in a wireframe toolpath to show off.

here i have the Machine setup defined at the WCS Origin (bottom left corner of the geometry), toolpath starts at the bottom right of the square, direction arrows shows the toolpath i am cutting moving from X2 Y0 to X2 Y2 and so on

This is with the output set to use Real Machine Zero

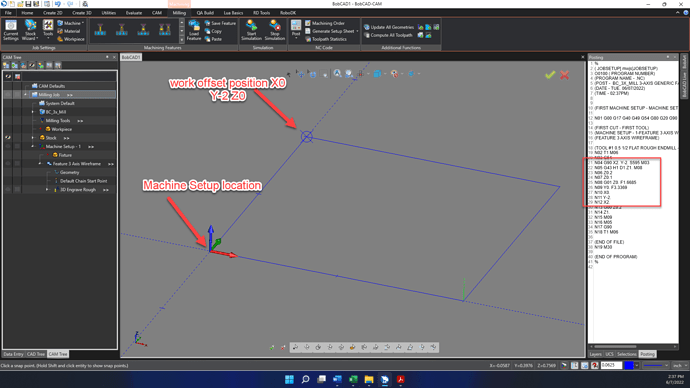

The same toolpath but my work offset coordinate set to the top left of the square and in Multiaxis posting it set to use Work Offset Position, look at my coordinates now, those are now with the work offset values added to the XYZ positions.

is this what you are looking to do?

Dont know why you need that in post processors.

Again keep in mind, these values affect simulation as well as if you set it to work offset position option in Multiaxis posting. So if you add Z value to stick your stock out in simulation and use the work offset position option to output, it will add those Z values too

hope this helps!

Gokul