As you guys may know, we have been digging in to all of these topics regarding tool numbering and tool assignment, and I plan to have a bunch of info to share coming soon, but just on the topic that @Bigman is bringing up about Copy and Pasting features from one Job to a different job (either in the same document, or in a different document entirely).

I am curious to hear everyone’s feedback on what you think the software should do in the following cases:

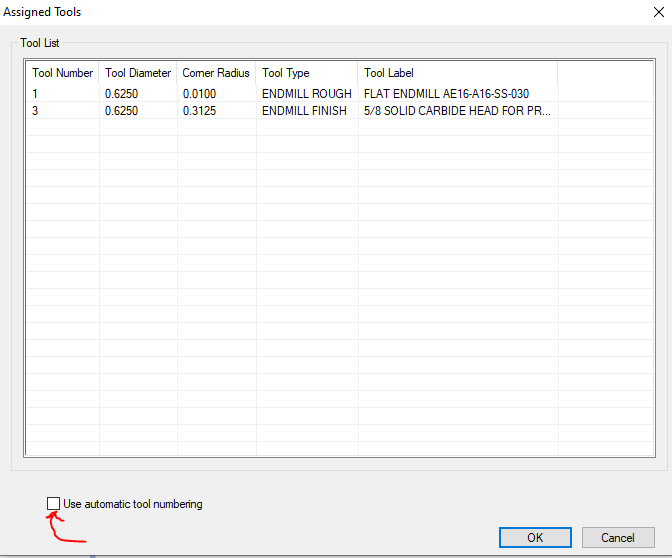

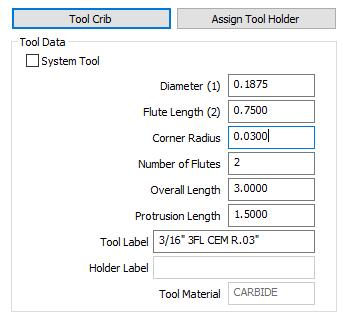

SCENARIO: You have a part fully programmed and your 3/8" flat rough end mill is tool number 6… (doesn’t matter which tool really, but for this example let’s just say it’s your 3/8" flat rough end mill with 3/4" of flute). For the sake of this conversation let’s assume that you have Automatic tool numbering turned off.

You are working in a new file on a different part like above in Big Man’s example so you copy the feature from Part 1 and paste it in Part 2’s job.

CASE 1: The new job you just pasted your feature/operations into does NOT have a 3/8 endmill in the tool crib for the job already.

I think we can all agree the expected result here would be that the 3/8 flat end mill is added to your tool crib and it keeps the T6 tool number?

So what would you want to happen though if a different tool already had tool number 6? (this is where the difference in Automatic Tool Numbering vs Not Automatic), so since in the beginning we said, hey lets assume automatic is off:

If automatic is off, there are two solutions:

-

We just simply add the tool the crib, and now you have two tool number 6’s which are two different tools. Would you want a warning or a pop up message or something to alert you to go fix this?

-

We give a new number to the tool, and you are going to need to go fix it anyways.

CASE 2: In Part 2, you already have this 3/8" flat endmill in your crib and it happens to be Tool #4, so when you paste the feature/operation that was using the 3/8" flat endmill set to tool 6, what would you want to happen?

Current solution: Have the system say hey, he is using this 3/8" end mill with the same flute length already, lets just grab the existing tool (which is the same tool) and set it to Tool #4 (since its already in the crib and in use).

What other flow might you want to see?